This page contains plates or diagrams of early tools, some used for pianos, some for musical instruments, and others for more general applications. These basic cabinet makers tools are included as well, because many were used in the piano industry.

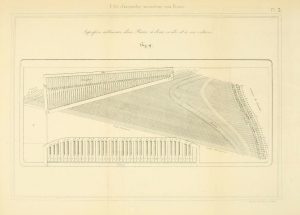

Here are plates from Giacomo Ferdinand Sievers’: “Il Pianoforte: Guide Pratica per Costruttori, Accordatori, Dilettanti e Professori di Pianoforte.” Published by Ghio, 1868, in Naples. In 1833, Sievers began his career as a pianomaker in St. Petersburg, Russia, then he moved his factory to Naples, Italy during the 1860s. Many of the procedures and tools described in this book were a good generation or two old by the time of its writing. Anachronistic as this book was, Sievers provided a detailed description of piano making as it was practiced in the early 19th century. It was a period when the piano was undergoing dynamic change as every year passed. While modern pianos are a combination of hand work and machine work, Sievers was describing piano making at a time when the Industrial Revolution had somewhat less of an influence on the building process, and pre-industrial hand work took a larger portion of that process. This 1800 to 1850 time frame represents what we now recognize as the later fortepiano period. Famous fortepiano makers from that time would include Anton Walter (1752-1825), Conrad Graf (1782-1851), and Johann Baptist Streicher (1796-1871). With the publication of “Il Pianoforte…”, Sievers provided some rare insight into the making of these early instruments, which have been actively reproduced in the last 45 years. These are plates and illustrations which illustrate the hand tools and equipment which were used in Siever’s piano manufactory:

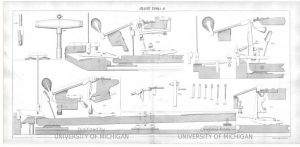

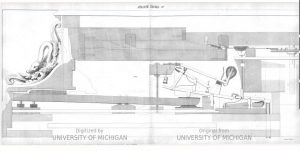

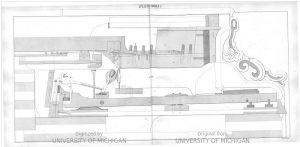

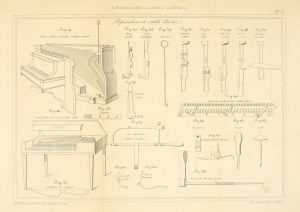

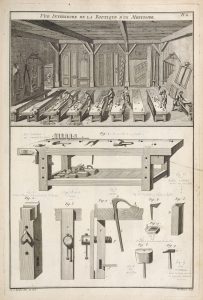

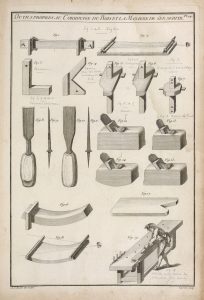

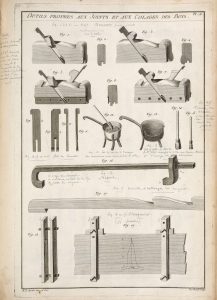

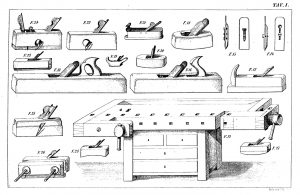

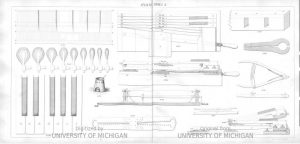

Illustrations of a workbench and a range of wooden bench planes, as shown in Siever’s “Il Pianoforte…”

24. fillister plane; 22. rebate plane; 21. 18th century iron mitre with proud sole and tote at nose; 18. coffin smooth plane; 17. large smoother, German/Austrian type with horn on nose; 14 and 15. 2 plane irons (long and short screw types) with cap irons (chipbreakers), 23. radiused plane; 13. jointer plane; 16. jack plane; 19. Dutch gerf plane; 20. toothing plane; 25. nosing plane; 26. plow plane; 28. convex plane; 12. cabinet workbench with vises. 27. compass plane.

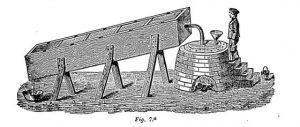

The following is an English translation of Siever’s seasoning process provided by Edward Swenson in “The Tools of Early Piano Building,” from the December 1989 Piano Technician’s Journal:

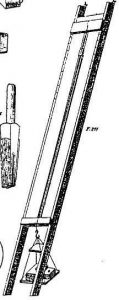

An hermetically sealed boiler with a bolt-down lid containing approximately 20 buckets of water, and perfectly walled in by an oven of bricks, would be the major expense of this apparatus. A box of strong fir, four meters long, 85 centimeters high and 65 centimeters wide, with a tight lid forms the second part. This box placed obliquely with one of its ends toward the boiler, receives the steam by means of an iron pipe–while the other end, placed at about 30 centimeters from the ground on fixed supports is furnished at its lowest point with a hole which allows an exit for the water condensed from the steam.

The pieces of wood, cut to the desired dimensions, are stacked like knives upon the little bridges in the box, with many little wood spacers inserted to prevent the pieces from touching. The cover is closed tightly and the apparatus is ready. The boiler must be maintained for 48 hours. Every three hours one adds the necessary water introducing it by means of a funnel fixed for this purpose in another pipe in the cover. The wood may be quite green, for the steam purges it of all the noxious substances which exit as a tincture as black as ink. Before removing the wood from the box, it is necessary to let it cool for six hours. When removed the pieces are swollen and wet; placed in a dry and airy location they dry out rapidly, become light (in weight) and pale in color, but they remain stable and neither crack nor warp. They become more easy to work and take glue most excellently.

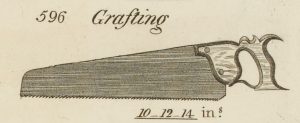

Grafting saw (with small nib) from “Explanation or Key, to the Various Manufactories of Sheffield, with Engravings of each Article,” by Joseph Smith, published in 1816.

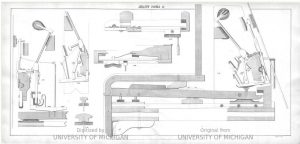

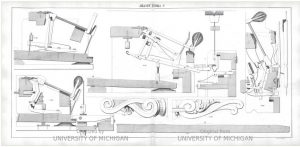

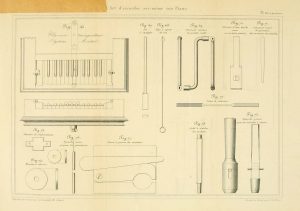

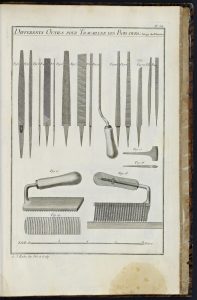

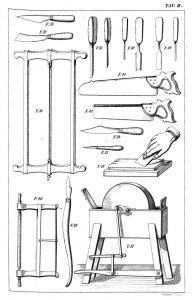

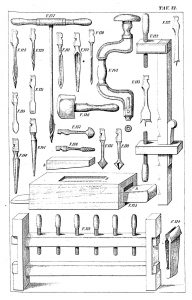

39. two man, four hand felloe bow saw; and 40. standard bow saw; 37. foot powered grinding wheel; 32, 33, and 34. felt, cloth, and leather cutting knives; 25 and 36. wood carving knives; 29, 30, and 31. various chisels, gouge; 41. small panel saw (18th century grafting saw profile); 42. carcase, or back saw; 38. edge tool honing plate.

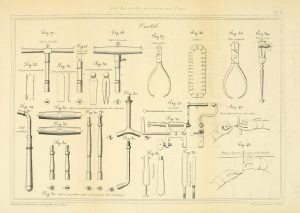

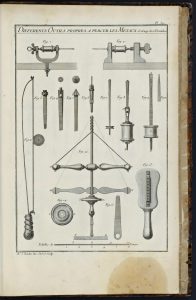

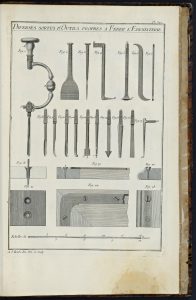

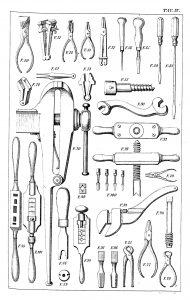

80. damper felt compression pliers; 71. hand vise; 78. key easing pliers; 79 expanding pliers for kapsels on Viennese grand pianos; 81. round nose pliers for wire; 72. slide-tongs type pin vise; 86. awl; 83,84, 85. English pattern Sheffield screwdrivers; 92, 93, and 94. male and female screw taps and handles for making wood screw threads and sockets for piano legs; 95 and 101. metal screw tap ‘T’ handles; 98. metal tap handle, lever type; 82. tweezers; 90. wrench; 70. heavy metal vise with post leg; 91. early adjustable wrench; 88. with 89. spanner screwdriver and divided nut; 75. nippers; 77. flat nose pliers; 76. small end cutters; misc.

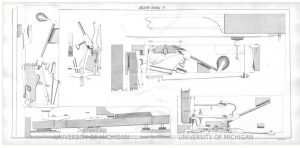

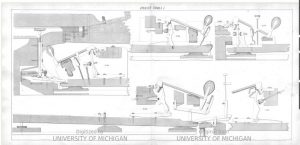

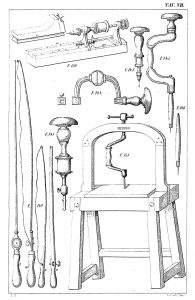

150. Fixed bow drill; 148. small German style bow drill stock; 145. Pianomakers brace, with 2 tapered pads; 144. Gentleman’s ‘penny’ brace; 147. full size German bow drill stock; 149. Four drill bows, three ratcheting, and one traditional; 151. Heavy drill press, requiring two people to bore into dense and thick hardwoods.

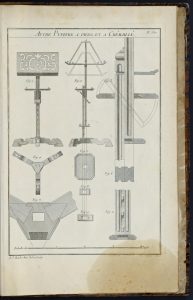

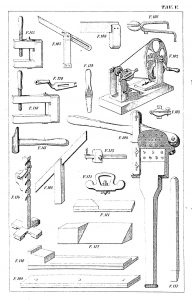

102. screw threading machine; 103. sheet metal shears; 104. music wire cutting machine (with holes for cutting different diameters); 105. mitre square; 106. square; 107. bevel gauge; 113. mortise gauge; 114. jack, for use with grand leg removed; 115 and 116. wood “C” clamps; 118. axe sledge hammer; 119. hole punch for cloth, felt, and leather; misc.

143. English Sheffield bit brace with button lock chuck; 127. breast auger; 122. piano makers long vise; various spoon bits, countersinks, center, reamer, burnisher, rasp; 123. clamping press; 125. wedge adjusted jig for planing various pieces of wood to equal thickness; 126. wooden mallet; misc.

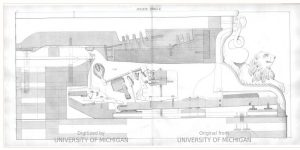

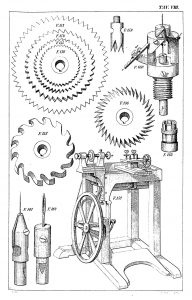

152. Combination treadle saw, lathe, and horizontal drilling machine; various rotary blades, drill bits, etc.

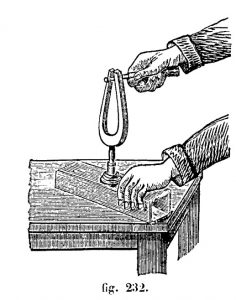

Simple voicing tool.

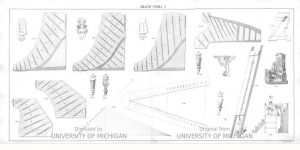

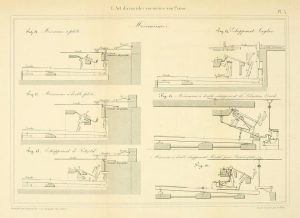

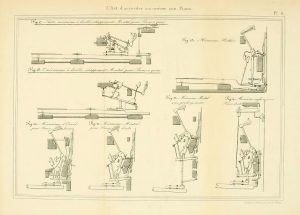

Various action diagrams:

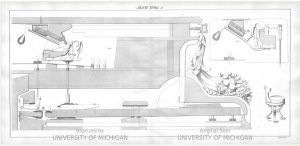

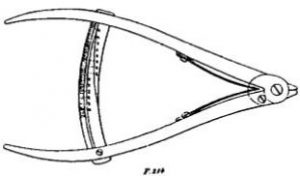

217. Lamp glue pot; 212. bass string lathe, or winding machine.; outside caliper; 213. and 214. music wire gauges.

211. wire testing machine for measuring tension at failure. Head of wooden string mute for tuning, left.

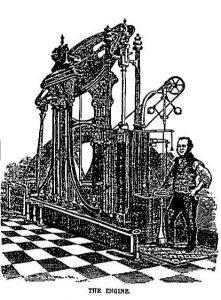

Early 19th century factory steam engine. It looks as much like an entrance to a carnival ride to me.

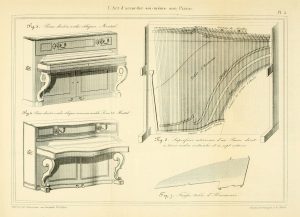

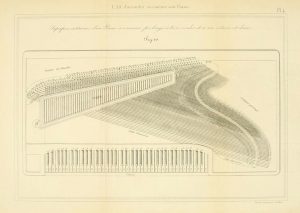

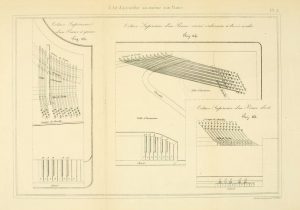

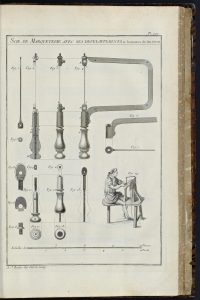

Montal: “l’Art d’accorder soi-même son piano…” Claude Montal (28 July 1800 – 7 March 1865). This 1836 book was the first comprehensive treatise on tuning and general piano work. Montal was a tuner, and later, maker of pianos.

From left to right: Metal tuning hammer oblong socket; Square socket; Wood-handled tuning hammer, removable tubes—for oblong and square pins; Interspersed, three types of mutes, for silencing certain strings during tuning; Flat-nosed pliers; Music-wire gauge; Piano-wire cutters; Hand vise Tuning lever, gooseneck, with stringing hook; Components for two universal style tuning hammers; Two tuning forks (diapason) and case (#34 used to draw between the tines to sound the pitch), and looping/braiding machine. Illustrations in the bottom right show loops and braids being made for the single strings, and then in the lower one the string being wound on the pin, which does not have a string becket and hole (as in modern tuning pins)

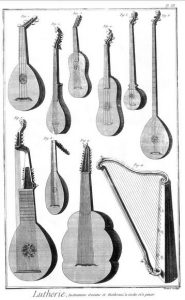

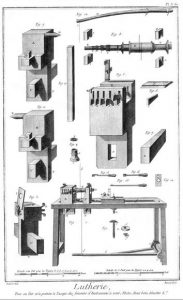

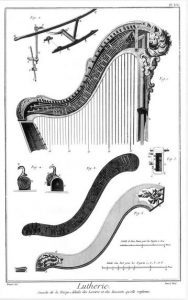

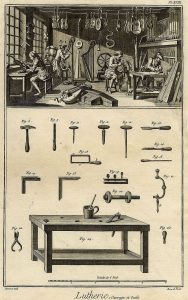

Diderot, volume 5, plate 18. “Music instrument making, works and tools.” Circa 1767, Picture includes violins, violas, a clamped up bass, harps, organ pipes, a 17th century guitar, a lute, virginal, and hurdy gurdy. A luthier is working on the face of a violin or viola, with a hand plane.

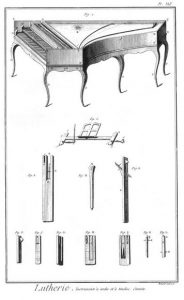

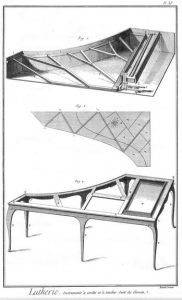

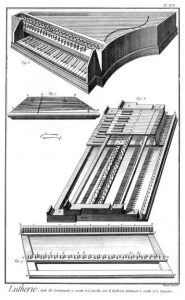

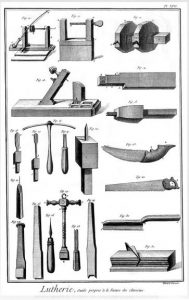

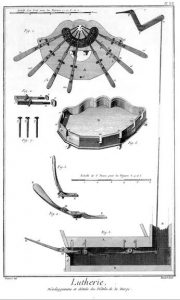

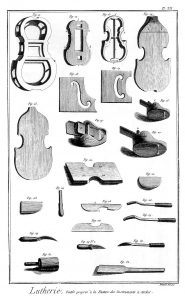

Diderot: Encyclopédie Volume 5. “Lutherie.” (1767) Denis Diderot collaborated with Alembert over several years to make this compendium. Here are some plates from “Lutherie.”

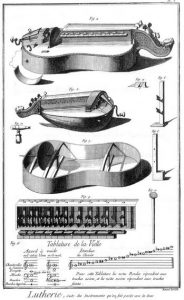

Diderot, volume 5, plate showing stringed instrument components and three ovoid shaped violin planes. By the 1760s, luthier planes had developed into the basic design that is still used today.

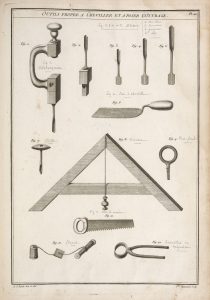

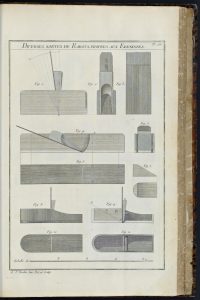

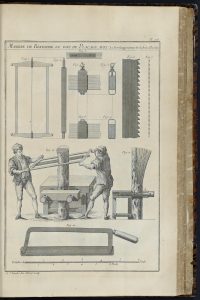

Roubo: L’Art du Menuisier. André Jacob Roubo (1739–1791) an accomplished cabinet maker, wrote this book between 1769 and 1774. The following are selected plates from that book. L’Art du Menuisier vol.3 can be seen here.