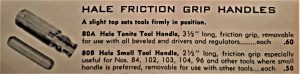

Adjustable handles for piano regulating tools became popular for the mobile piano technician relatively soon after their introduction around 1900. Since a good number of regulating tools were made to be compatible with it, including screwdriver blades with sizes up to 5/16″ for general driving, these handles were used constantly. In order to accommodate the different functions of all these tools, Frank Hale at Tuners Supply in Boston offered their combination handles in small, medium, and large sizes. As far as I know, there is no current supplier who offers three sizes, and Hale was not known for having a selection of tools as large as Hammacher Schlemmer or American Felt Co.

With using combination handles, piano tuner technicians were able to save space and lighten their load when carrying their toolkit from job to job. When field work was done in a large metropolitan area, and public transportation was used, every extra ounce of weight made a difference. I can attest to this personally, as I used to take the subway to various jobs during part of my years at at Steinway Hall in Manhattan.

By going to combination handles, instead of individual handles for each task, the piano technician gained something but lost something as well. Individual handles would be made specifically appropriate for a given task, but they would be bulky and unwieldy when carried in quantity. When Hale offered three sizes of adjustable handles, he was attempting to compensate for this loss of appropriate specificity. A good example of correctly-sized handles for the tool and the task can be found among selections of good vintage and antique chisels; many modern chisels though, no longer have appropriately sized handles. Because adjustable piano action handles were in use so frequently for a large range of tasks, it was important that the handle be appropriate not only for the hand of the user, but for the tool that was attached, and for the specific task engaged.

Examples of handle matching:

- Small drop screw regulator, which was also for adjusting the grand balancier and the grand jack. This is a delicate and fine tool; the metal shaft is thin and the socket is small in order to pass between grand shanks, regulating buttons, and the most narrowest of places, let-off dowels encountered on many grand actions. In order for the hand to be close to the work performed, the shaft was made short. The handle is commensurately small, with a faceted middle section for situations where a little more resistance was encountered—facets also prevented the tool from rolling off the workbench. A deerskin covering for the index finger, thumb, or palm–depending on the particular task at hand–was applied with bridle tacks to the back of the handle.

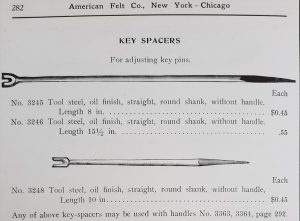

- A huge octagonal handle was used on the key spacing tool. Many key spacing tools from 1880 to 1920 were large and robust like this one, unlike the smaller ones designed for use in the combination handle. These larger versions of key spacers were intended for pianomakers, and the initial spacing during the set up of a keyboard required a more exerted wholesale movement of keys, rather than the touch-up that is generally performed in the field later on.

Selection of Key Spacing Tools, including a 15 1/2″ long Key Spacing Regulating Tool, as sold in the American Felt Co., 1911 Catalogue.

It is also why, I believe, there are many early key spacers which are longer than 15 inches, not including the handle: it allowed the regulator to stand back and look at the entire keyboard at once, without having to stop working. Stock Nos. 3363 and 3364 were Tuck cocobolo handles, London pattern, to be individually fitted to each tool.

Subtle advantages of correct handle matching manifest with specialization and prolonged work at a single task.

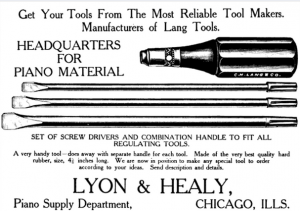

C.H. Lang’s Combination Handles

C.H. Lang Combination Tool Handle, hard rubber.

C.H. Lang, 1905: “All regulating tools to fit [handle] 20 cents extra, which is nothing compared to all the trouble with the wooden handles.” Lang also referred to the problem of splitting wooden handles, which happened often when the tang was inserted with too much force.

Shown below is an unmarked combination handle, with ebonite instead of hardwood, and metalwork that matches that of the Lang machine shop. This adjustable handle was designed to take the standard interchangeable regulating tools that we use today, but with a friction fit, rather than a collet. I believe that C.H. Lang offered this handle without including it in his 1905 catalogue; further down this page, another friction fit adjustable handle is shown, with American Felt Co. details, but also not included in their catalogue.

Another image of the original Lang Combination Handle, as advertised by Lyon & Healy. From “Tuners’ Magazine,” August, 1914.

Immediately after buying out Lang’s machine shop, Lyon & Healy continued making all of Lang’s piano tools, complete with the Lang proprietary stamp. After a year or two, this changed, and the Lang name was eliminated from catalogues, advertising, and the actual tools. Unlike most of the other ex-Lang tools, the Lyon & Healy Combination Handle (version 1 shown here) would go through two more iterations during the short tenure of L.& H., which ended in 1928.

Lang’s policy of exclusively selling piano tools was changed immediately. Lyon & Healy promptly added piano materials, hardware, and parts for their line of piano supply merchandise.

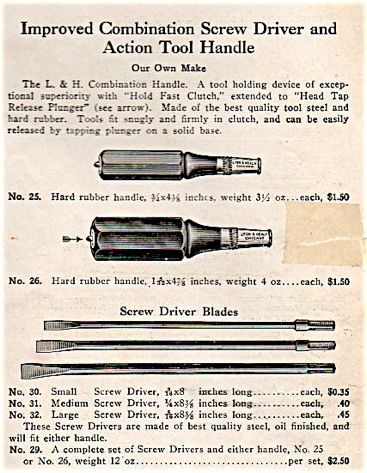

Lyon & Healy combination set (version 2), handle made of ebonite, fairly similar to C. H. Lang’s before it. These proprietary L.&H. tools have a square base which were designed to work with this particular handle only.

The proprietary L&H tools have a square base which were designed to work with this particular handle only. To release, you depress a tab on the back of the handle by tapping down on a hard surface. It works well (as long as one doesn’t do this on the piano cabinet!). Circa WWI era.

L. & H.Combination Handle, Version 2, 1916 Catalogue.

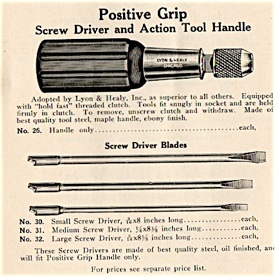

Lyon & Healy Combination regulating handle (version 3), as advertised in their 1926 L.& H. Catalogue.

Only two years before Lyon & Healy exited the piano supply business, and sold out to Tonk Brothers, they saw that offering a combination handle which accepted the standard used by American Piano Supply (1914-1927, pre-Hammacher Schlemmer), and Hale would be the way forward. This particular handle (L.& H. Version 3) looks like it may have been a repurposed conversion from a more general purpose interchangeable handle, but version 3 has a ferrule similar to version 2, so it was probably made in house.

Hale’s Combination Handles

Hale Combination Regulating Tool Handle, offered in 3 sizes; in Dark Walnut-Stained Hardwood, or optional Rosewood. 1938 Hale Tuners Supply Catalogue.

Hale combination handle 1938. Three sizes were offered, from the late 1920s, until c. 1942, which was a lot considering the rather spartan amount of tools offered in the Hale catalogs. Today, two sizes, at most, are available from any one supplier of combination regulating handles.

Hale Combination Regulating Tool Handle, offered in 3 sizes; in Dark Walnut-Stained Hardwood, or optional Rosewood, for 25¢ extra. 1940 Hale Tuners Supply Catalogue.

Tuners Supply combination handles. Top, Hale small size, in mahogany, with Hale upright backcheck wire adjuster; Hale standard size, 1930s, with Trefz key spacer.

Hale Combination Regulating Handle, produced from the 1920s to 1942, with crosspin to counter torsional stress, and floating brass collet. Yamaha Combination Regulating Handle, c. 1990s, with crosspin and floating brass collet, which they copied.

Hale Stationary Regulating Tool Handle, c. 1940, for individual handles; Hale no longer made regulating tools with a tang, they were glued into individual handles with the interchangeable base. By 1940, very few mobile technicians chose this option.

Hale’s regulating tools with individual handles were not promoted after the introduction of their combination handle and interchangeable regulating tools circa 1905. Hale discontinued making their regulating tools with tangs and separate handles shortly after WWI. In 1940, Hale workmen would fit old regulating tools and screwdrivers to this handle for the 20¢ price of the handle.

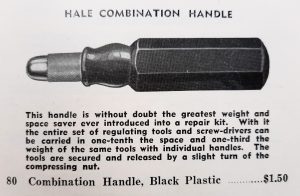

Hale went from hardwood handles and optional rosewood handles in the early 1940s, to a durable black plastic, right after World War II. In their March, 1957 Catalogue, Hale stated that they introduced the interchangeable handle to the repair trade “over 50 years ago,” or circa 1905. This was around the same time as American Felt Co. and Hammacher Schlemmer brought their versions of the interchangeable handle to market as well.

Hale Combination Handle; black plastic, and only available in standard size. From Hale Tuners Supply 1948 Catalogue.

The black plastic was very strong, and was resistant to the most careless abuse. I know one well-known piano technician who used his Hale handle for playing fetch with his dog!

Original Hale “Friction Grip” handles, in mahogany, with No. 25 German Silver center pin as locking bar for the inserted tool. I purchased these new from Hale in the 1970s. The Hale drop regulator is 3 1/2″ long.

Hale small Artwood Tool Handle, sellout at 1952 A.S.P.T. Convention. Advertisement in “The Piano Technician,” October, 1952.

The Hale small Artwood tool handle was a prescient idea, which anticipated other small regulating tools such as the Yamaha and Wessell Nickel and Gross drop regulators. They would probably sell well today, but it is easy to make your own out of a choice of hardwoods.

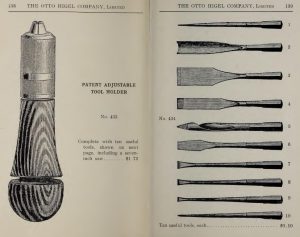

Early General Purpose Combination Tool With Hollow Handle for Storage

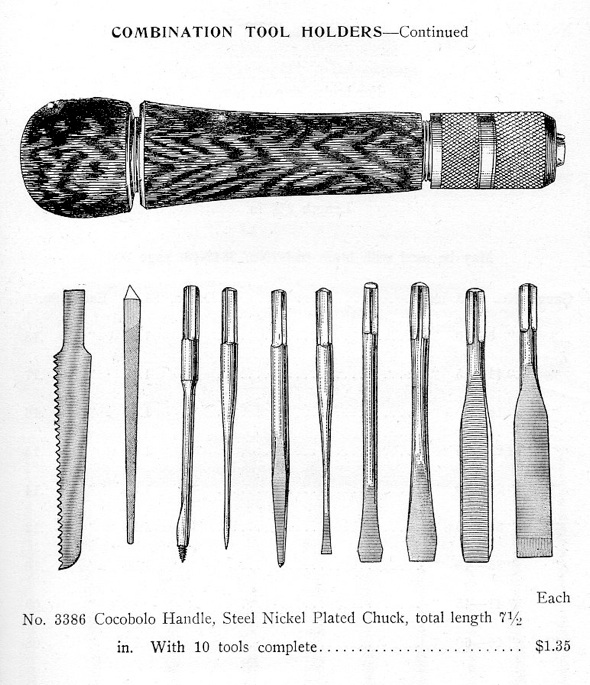

Here is an early example, by Millers Falls, patented Jan. 14th, 1868 (Amidon jaw chuck). This same chuck was also used on the Millers Falls #16 brace, which was intended for pianomakers. No. 16 had an unusually narrow 4-3/4″ sweep, consistent with the traditional pianomaker’s wooden braces, and was manufactured from 1884 to 1901.

Millers Falls Multi-Tool Handle, Patented 1868, and offered in period piano supply catalogues.

Stanley No. 55 Combination plane; marketed to supplant a large toolchest full of moulding planes. Photo by Jim Bode.

During the Civil War, soldiers were required to perform multiple mechanical tasks, in order to maintain all the artillery, and other equipment on and off the battlefield. With other new technologies, such as the telegraph, the railroad, and anesthesia, came the need for technical support and and maintenance. Veterans of the Civil War were often “jacks of all trades;” back in the Reconstruction era, this did not have a negative connotation, it was an advantage. Wishing to utilize the new skills learned in service of their country, Civil War veterans wanted to use a large range of hand tools. Not everybody had the resources or the space, however, to buy a large amount of tools: this created the market for multi-tools, such as the Millers Falls Multi-Handle example patented in 1868, and also the Stanley Combination planes, such as the Nos. 45 and 55.

Tool disassembled, showing chuck and tools contained in hollow handle.

Miller Falls handle in the 1911 American Felt piano catalog.

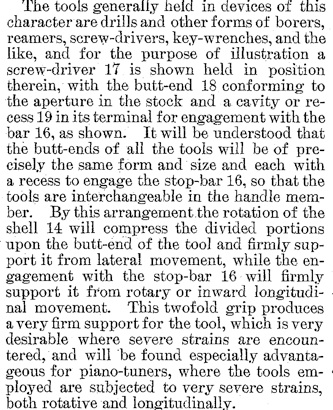

A difference between the Miller Falls type of tool handle and the patented handle shown below is that lateral and longitudinal movements of the tool are held in check by two separate functions in the tool, in a way not unlike the present piano regulating combination handle. This differs from the older tool handle above, in which both potential movements of the tool bit are controlled by one piece of hardware, the collet, or in this case, the chuck.

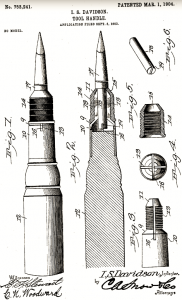

The “severe strains” L. S. Davidson is referring to would seem to be more related to tuning tools, rather than regulating tools.

L.S. Davidson’s combination handle was the earliest US tool handle patent—with a reference to piano work—that I’ve found. Here is some of the text for the 1904 tool handle patent:

Pad Handles, Dating back to the 18th Century

Going back further in time for multi-tools, we have the Pad handle, which was included in the 1791 tool inventory of Christopher Gabriel. The chuck accepts a smaller version of bits made for the brace, with a nick cutout to engage the spring lock. This particular rosewood pad handle by Bagshaw & Field was a late example of the type, circa 1880.

The Pad Handle was developed in the late 1700s in order to cater to the desires of an emerging class of wealthy British individuals, who owned their home, and were desiring nice things, for maintenance tasks around the house, but also for hobbyists, who wanted to work on personal projects in their free time. Companies such as Holtzapffel and Moseley, in London, would market their attractive tools in upscale showroom settings in retail districts. In Birmingham, and the English Midlands generally, these small tools were called “toys,” during the 18th century, and possibly earlier. The term “toys” also applied to small practical objects, such as hooks, hinges, and buttons made of various materials. Not until the late 19th century, was the word toys associated with playthings for children in England.

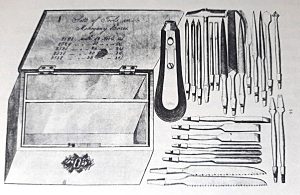

This Richard Timmons “Setts of Tools” included a wide range of interchangeable hand tools and Mahogany Box with ornate escutcheon. From a Birmingham trade list pattern catalogue, circa 1810.

Drawing of the Pad Handle and tools, from the 1845 Richard Timmins of Birmingham, England Catalogue.

More Early Piano Combination Handles

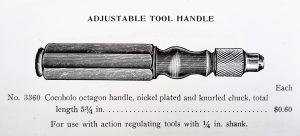

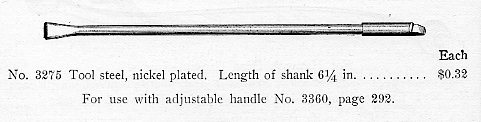

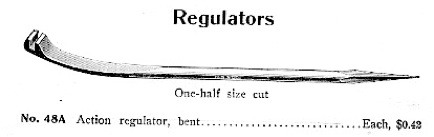

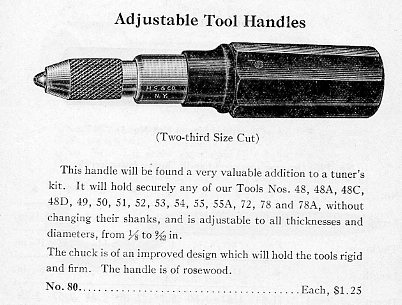

Between the turn of the twentieth century and 1910, all the major piano suppliers offered their own version of interchangeable combination handles for action regulating tools. The American Felt Co. drawing of their Adjustable Tool Handle was retained for the subsequent American Piano Supply (A.P.S.) Catalogue from the mid-1920s.

American Felt Co. 1911. This is the standard type, with angled cutout at the 1/4″ base of the tool. Its still the standard ‘clutch’ design used today.

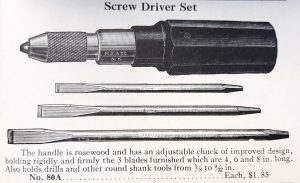

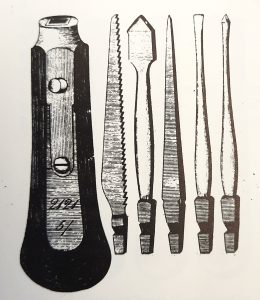

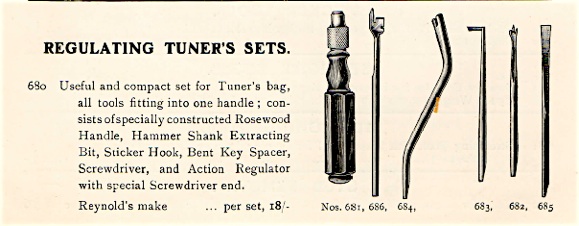

R. Reynolds Regulating Tuner’s Set.

Richard Reynolds, a piano tool maker in London, made this combination regulating set, c. 1920. The handle looks much the the American Felt combination handle, c. 1911. No. 686 is a wire bending tool with a screwdriver attachment, which is a regulating tool unique to England.

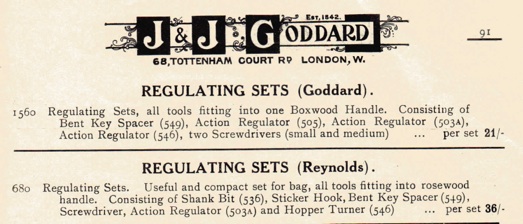

Two choices of regulating sets were available in Goddard’s no. 80, circa 1938 catalogue. Reynolds products were consistently the more expensive choice across the board.

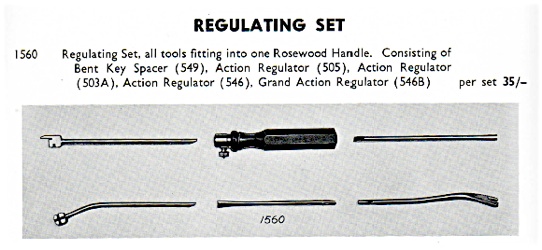

J.&J. Goddard Regulating Set with thumbscrew lock on handle, in the 1940s catalogue.

In the 1940s, J.& J. Goddard in London moved to a thumb set screw instead of a collet. G. F. Baker offered a similar design in their c. 1950 catalogue, and Fletcher & Newman offered same in their 1976 catalogue.

Another collet and compression nut type, found with a pre-WWI toolkit comprising of Erlandsen, H.S., and A. F. tools. These also accept the modern or standard arrangement.

I’m not sure who sold these, perhaps American Felt Co. by process of elimination. H.S. offered combination handles that accommodated the traditional tang.

This is the same combination handle, from a tuner’s box of tools; it is similar to the examples shown above. Next to the handle, on the pallet, are interchangeable regulating tools.

Unmarked, with a London pattern handle, and hardware similar to the American Felt Co. example above.

I have not found the supplier for this unusual combination handle, but it is early; based on the hardware, and rosewood handle, I would estimate 1905-1915. It was found with a large lot of pre-WWI piano tools. Possibly sold by American Felt Co.

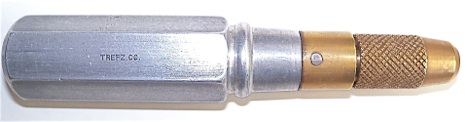

Trefz combination handle, aluminum, probably early postwar (c. 1946-1960s).

From Trefz 1935 catalog. Trefz carried the full Hale tool line in 1935, but I’ve seen a range of proprietary regulating tools, made post-WWII. Rebuilding supplies, however, were a focus of this company, and pinblock, bridge, and hammer duplication was prominently featured. A large range of grand hammershanks and flanges was carried as well.

These interchangeable tools will fit all of the handles shown above, and were made within that time period as well.

H. S. and Co. made their adjustable handles to be compatible with the traditional tangs found on piano regulating tools. c. 1918.

Traditional tang.

H. S. catalogue, 1925.

H. S. adjustable tool handle, disassembled, and same as the catalogue entry above, for use with piano regulating tools having the traditional tang. This handle does hold these tools securely. Since the traditional tang for piano regulating tools became obsolete at about the time this tool was produced, this one has had almost no use, as seen in the crisp edges of the facets of the octagonal handle.

H. S. adjustable tool handle, disassembled, and same as the catalogue entry above, for use with piano regulating tools having the traditional tang. This handle does hold these tools securely. Since the traditional tang for piano regulating tools became obsolete at about the time this tool was produced, this one has had almost no use, as seen in the crisp edges of the facets of the octagonal handle.

Hammacher Schlemmer Combination Handle to work with tools having traditional tang.

This is a handmade combination handle made from a modified drill chuck which was originally intended for use in a hand brace. The set screw fits inside a key spacing tool, and the socket accepts C. H. Lang regulation tools. I found this tool in Jonesport, Maine, in August, 1979, as part of a tuners set.

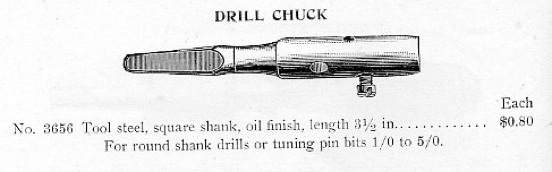

A drill chuck similar to the modified drill chuck fit in the above handle.

Same handle with Lang damper wire bender attached.

Combination Handles Made After 1975

A selection of more recent piano tool regulating handles, from bottom to top: John Ford, APSCO, Yamaha large, Yamaha small, Bolduc, Chinese large.