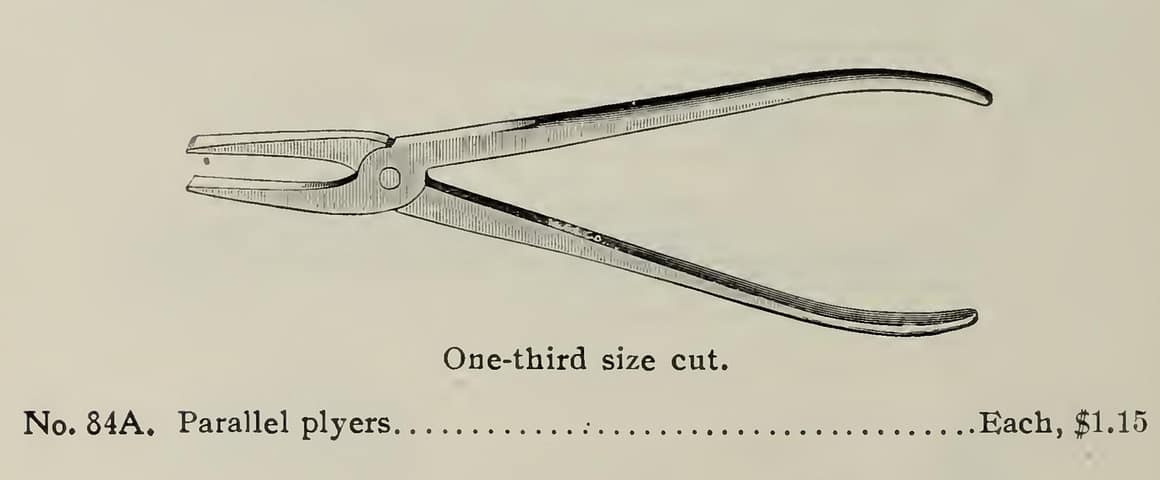

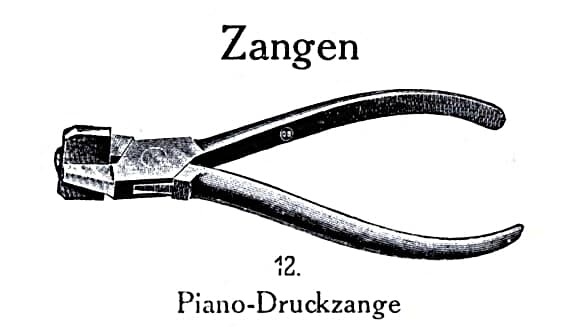

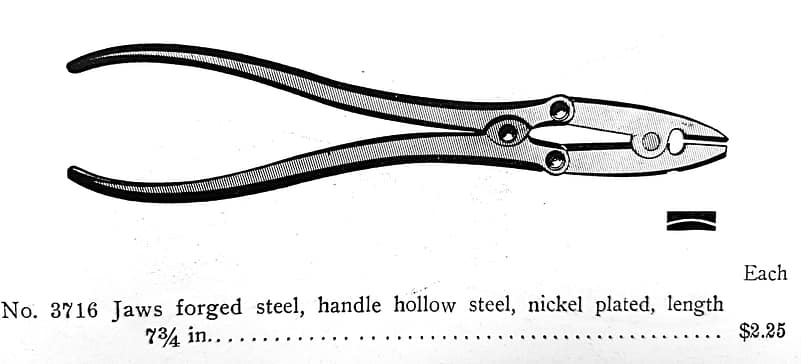

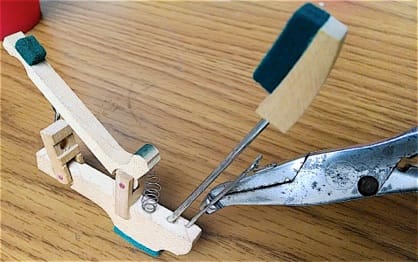

Parallel piano pliers–meaning that the jaws are parallel at the width of an average piano action part. Sold by George Buck. Similar to #566 in the Goddard catalogue.

For many collectors, pliers are typically thought of as strictly utilitarian, sometimes rather crude, and not holding much value as compared with other vintage or antique tool categories. Exceptions to this would include pliers from the 18th century and earlier, or unusually interesting patented examples. Often, pliers are paired with wrenches in large quantities as lots in antique tool auctions. Higher-end antique tool auctions, such as the David Stanley International U.K. (before 2017) or Brown International, generally do not include pliers at all.

Parallel Piano pliers, meaning that jaws are parallel at the average width of a piano action part. From Otto Bergmann, Berlin Piano Tool Catalogue, c. 1927

n the other hand, within the piano specialist’s user community, pliers have a rather elevated position, and some of today’s piano technicians will pay the $150 or more price tag for a specialized set of piano pliers, such as voicing pliers, either for needling or for compression. The various types of specialized pliers used within piano technology rivals that of earlier dentistry, in my opinion. Piano pliers are used for a wide range of tasks, from approximate and preliminary ones, to highly refined procedures.

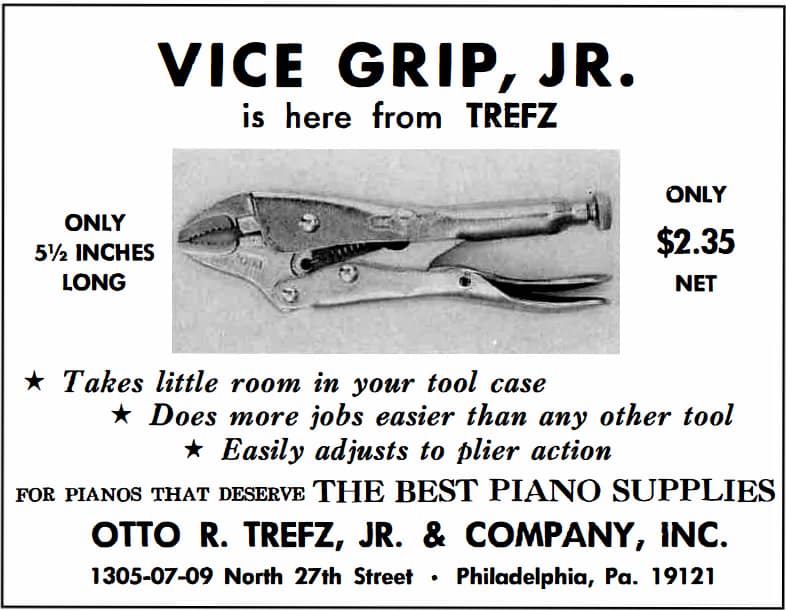

Vice-Grips, in new small size, as advertised by Trefz Piano Supply, in “The Piano Technicians Journal,” October, 1968. Vice (sic) perhaps a Freudian slip?

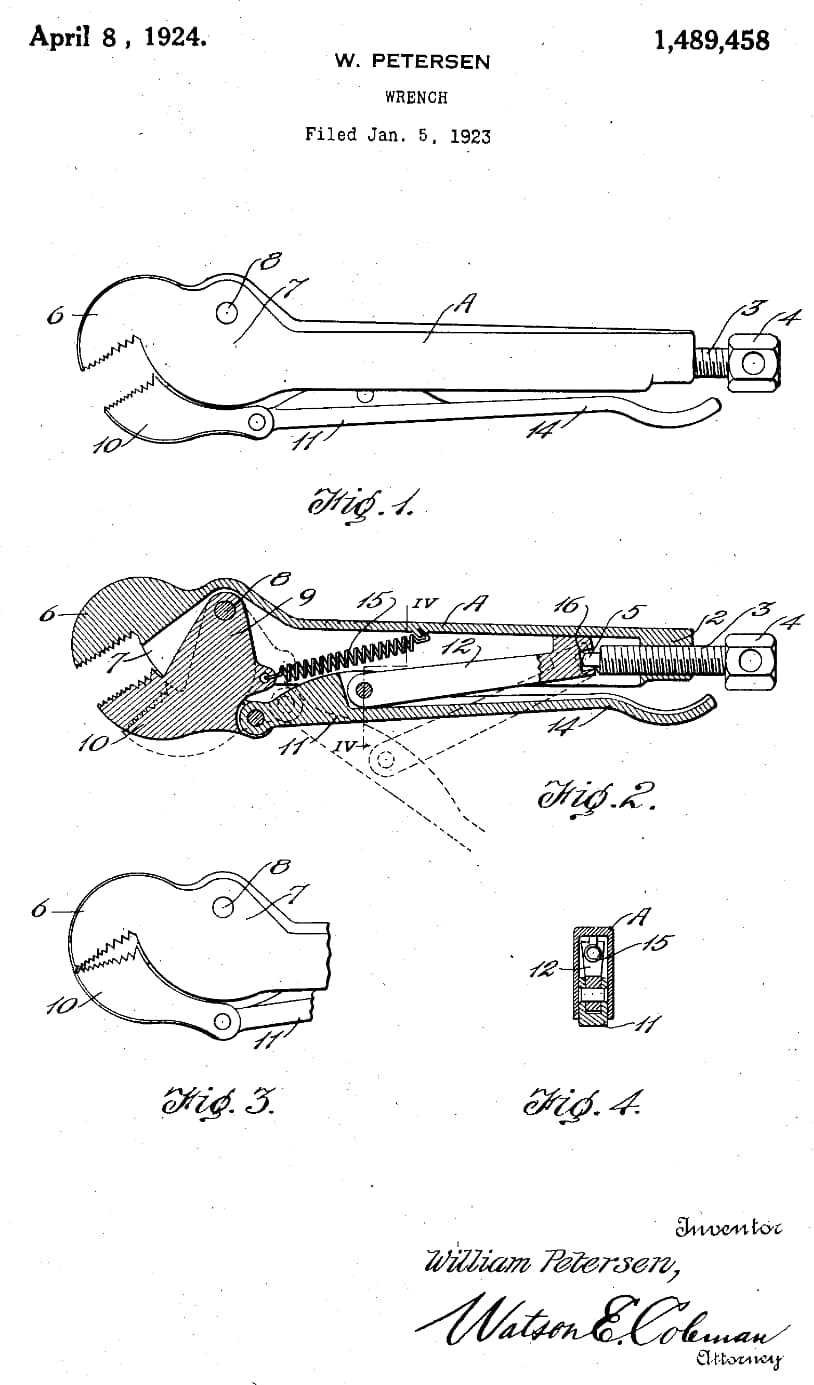

Vise-Grip locking pliers (second version), patented 8 April, 1924 by William Petersen.

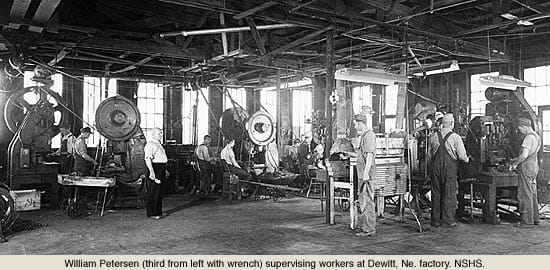

Photo of the Petersen Vise-Grip factory, Petersen, is third from left. Photo from livinghistoryfarm.org

William Petersen was a blacksmith who had immigrated to DeWitt Nebraska from Denmark. After The Great War, Petersen was looking for a way to hold his blacksmithing work while heating without having to physically clench down on his blacksmithing tongs. He invented the first version of his vise-grips around 1920, and he continued to revise and subsequently patent repeated iterations of his vise-grip locking pliers, until arriving at the version we know today in 1957, with the easy release lever. From the beginning, William Petersen made locking pliers by himself, eventually adding a few employees. By 1934, Petersen established a company, Petersen Mfg. Co., to produce his Vise-Grip locking pliers, and four years later, the first Vise-Grip factory was established in a former drug store in Dewitt, Nebraska with 37 workers. Vise-Grip pliers were manufactured in the United States under various owners until 2008, when production was outsourced to China. Malco Eagle Grip pliers were also made in DeWitt, Nebraska, but production was stopped in 2022.

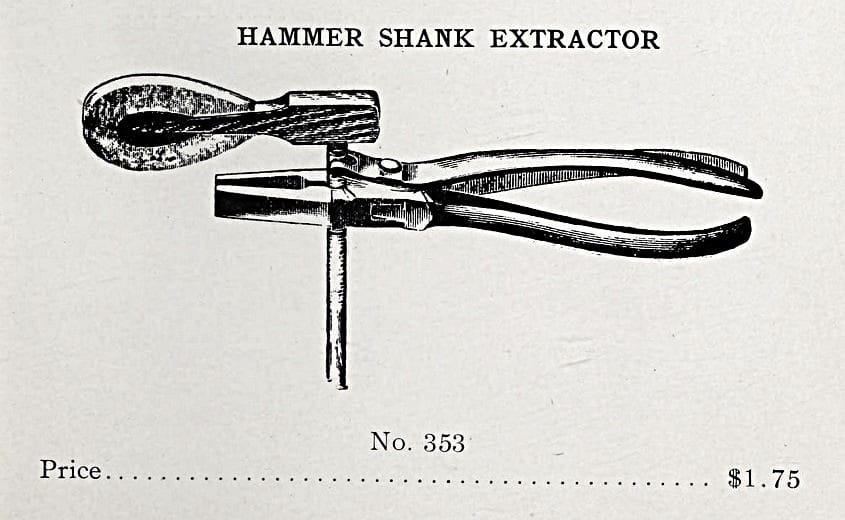

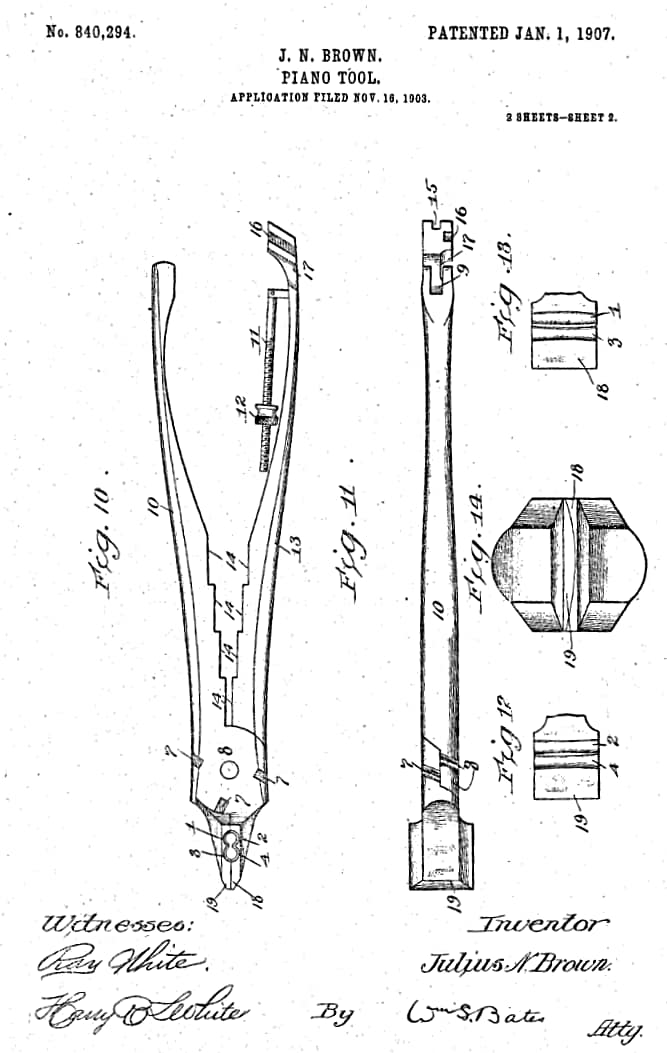

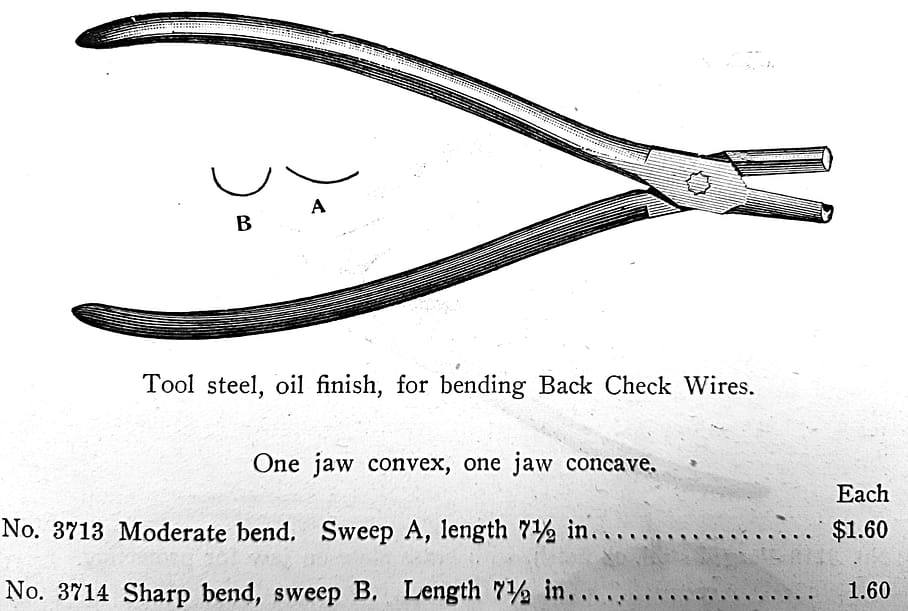

Extensive use was made of other standard pliers as well, such as needle nose, small flush cutter, duckbill, parallel duckbill, round nose, and leather punch. Pincers were used for grand knuckle extraction, and gas and burner pliers were used for shank knurling. After WWII, a new crop of specialized piano pliers were introduced for the following purposes: dowel capstan adjustment, damper creasing, hammerfelt compression. and grand hammer extraction. Plier-type hammer extractors were introduced circa 1902 by Franklin Hoover, shown further down on this page, and other designs soon followed. Various grand extractor types became important tools as more grand hammer replacement jobs were performed after WWII, and productivity was essential. Grand hammer extracting pliers, based on glazier’s glass breaking pliers. During the late 1990s, I was in search of an extractor that was hefty and would remove the old grand hammers quickly without damaging them. A number of local piano technicians got together, myself included, and paid a machine shop for a limited run of this tool. The result was a set of pliers that enabled efficiency with a minimum amount of damage to hammers or shanks, and was easier on the hands than some extractor designs made to this point in time.

Machinist made grand hammer extracting pliers. Grand hammers are drilled all the way through, and upright hammers are drilled approximately 7/8ths of the way through, so different types of extractors were used for vertical piano actions.

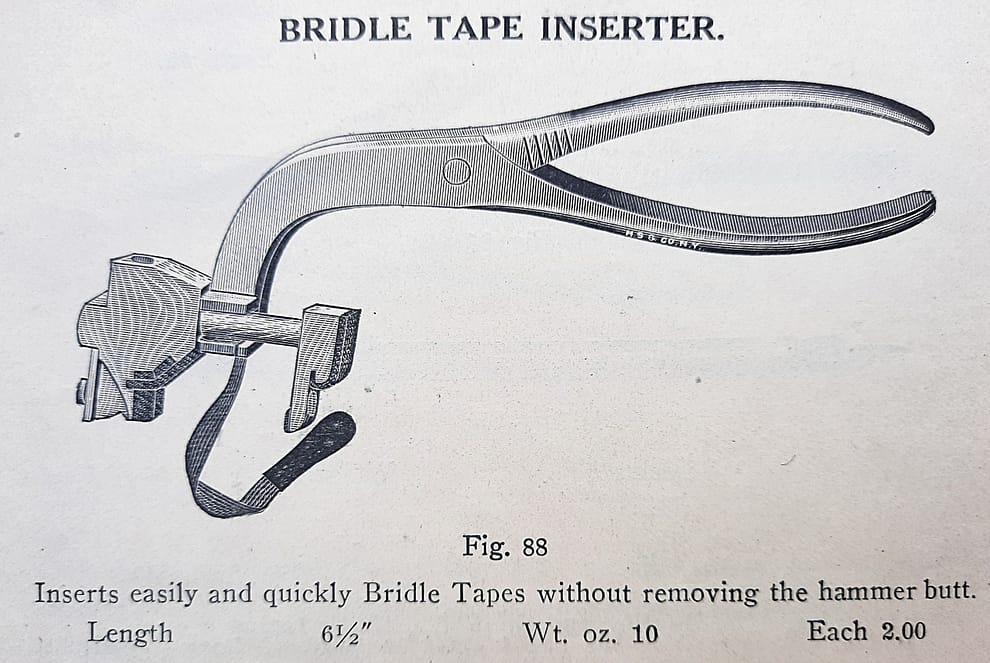

Two bridle tack inserting pliers, Boston Tuners’ Outfit, c. 1903, and compound action pliers, patented 1894. The tool on the right was made by Boston Tuner’s Outfit, not to be confused with Tuners Supply Company, in Somerville, MA. Boston Tuners’ Outfit was established by Charles P. Dolan circa 1904. Dolan did more than approximately copy the name Tuners Supply; he made some of his tuning tools with removable tips, very similar those made by Hale. E. Herman Gumpright (1865-1933) German: Gumprecht), a tuner and piano-factory technician, bought Boston Tuners’ Outlet from Charles P. Dolan in 1913. Gumpright continued to run Boston Tuner’s Outfit until 1928, and by 1930, Gumprecht listed his profession as a private piano tuner.

Final year for Gumpright (1928) and Boston Tuners Outfit at 113 Dudley St., Roxbury, in the Boston City Directory.

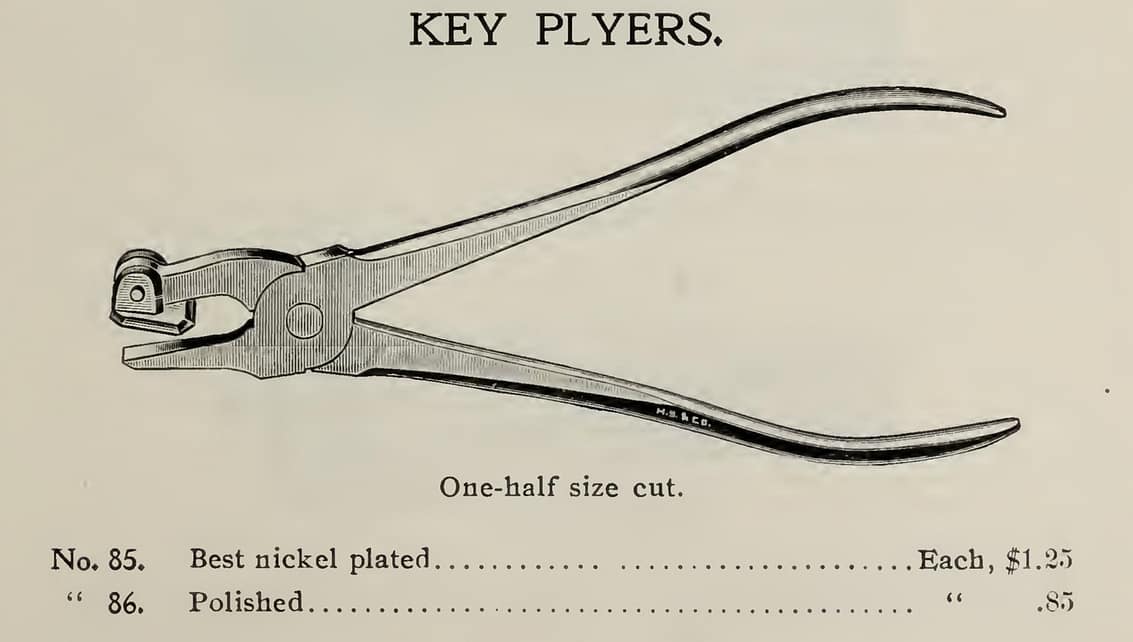

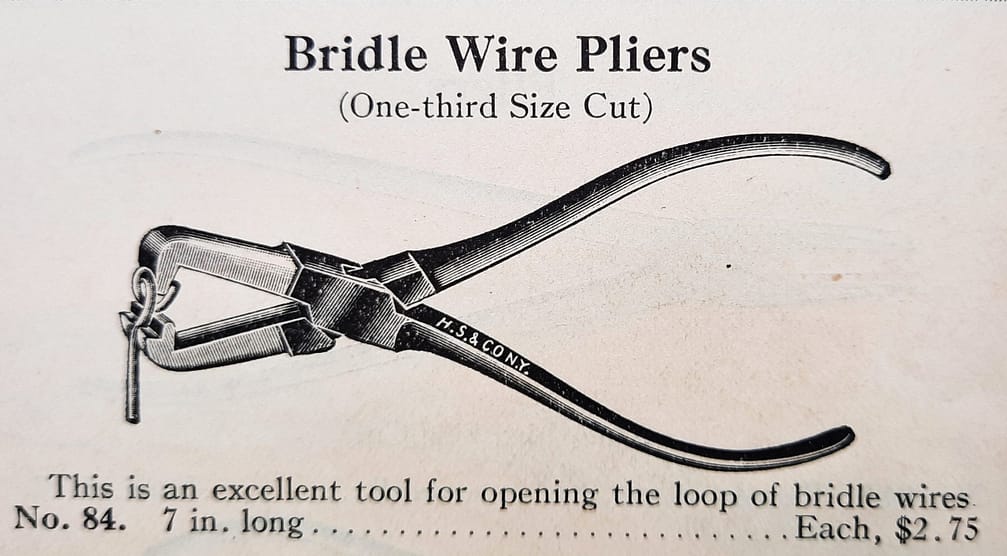

Boston Tuners’ Outfit Bridle Ribbon Inserter, by Charles P. Dolan, but stamped H.S. & Co. N.Y., and shown in the Schley Co. Catalogue c. 1905.

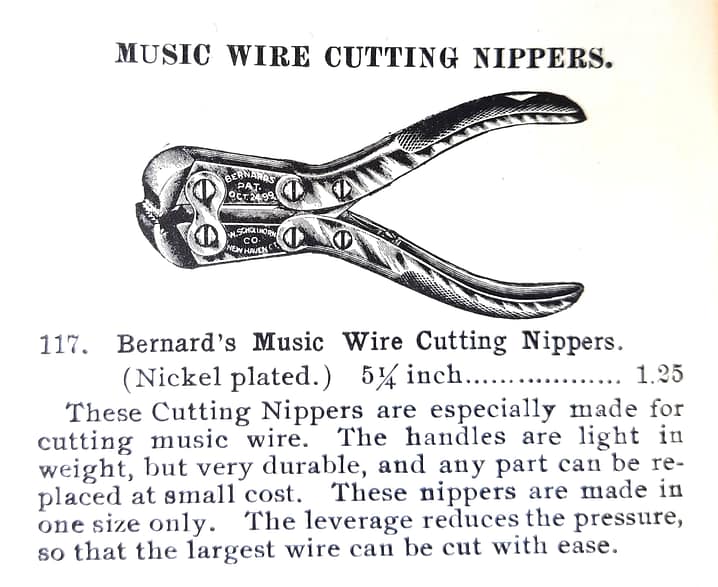

Music wire cutters, made by E. A. Berg of Sweden. Replaceable blades reflect overall quality of this tool.

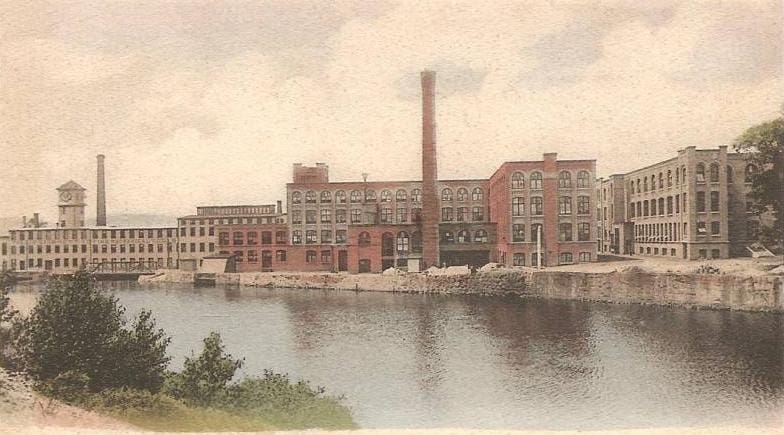

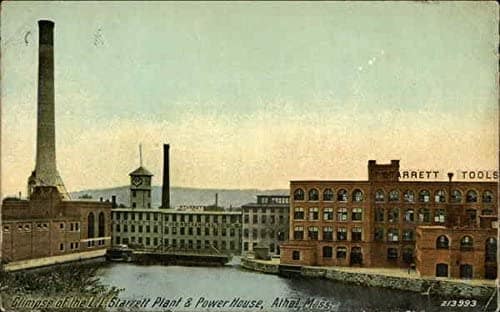

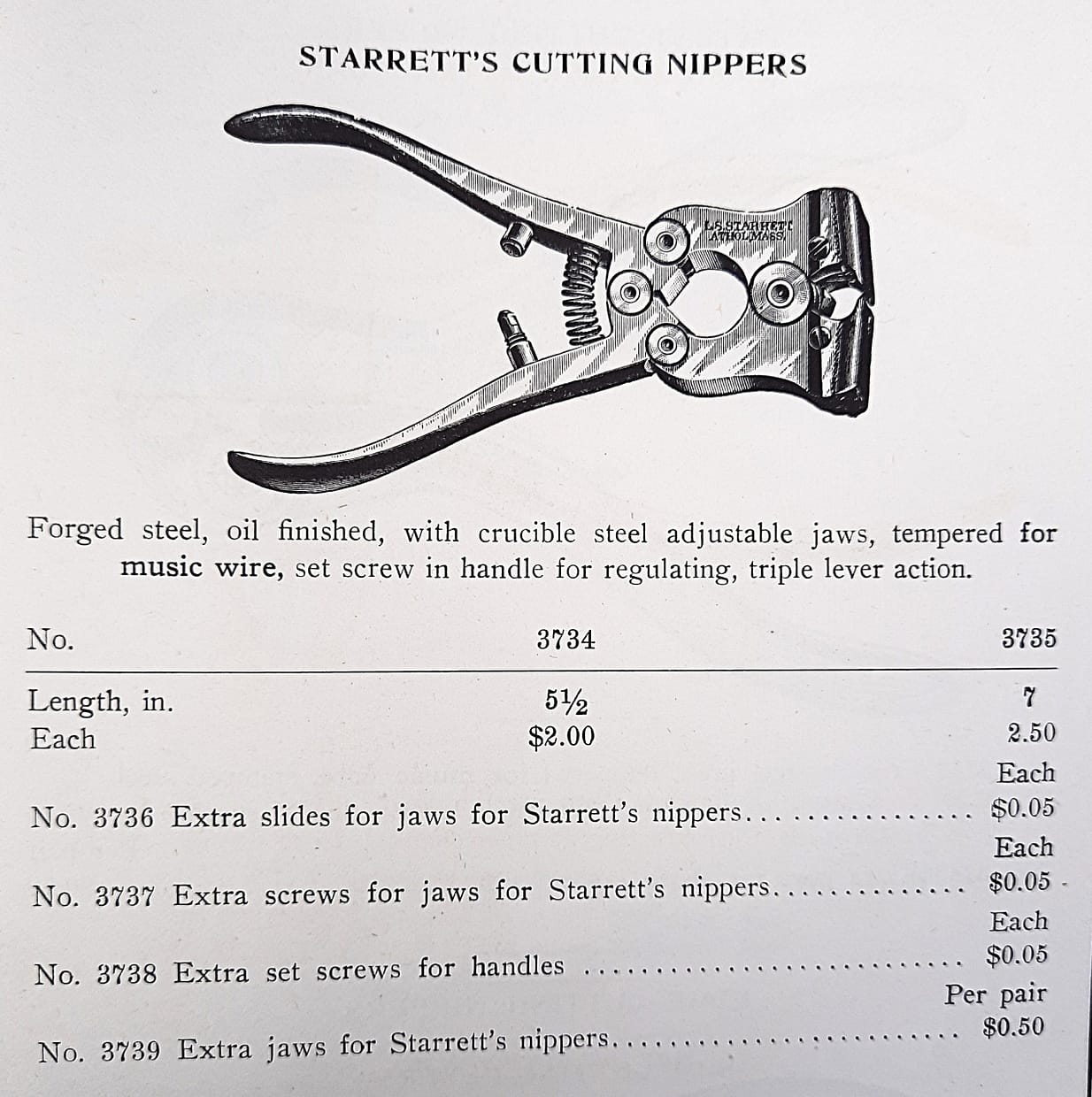

American Felt Co. 1911. These pliers are still available today from Starrett. Starrett also makes a music wire gauge, and a portable bottle jack, used to support the pinblock when stringing grand pianos.

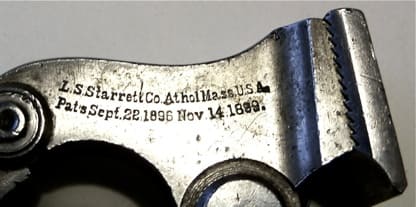

Close-up of Starrett engraving. This example was found in a tuner’s toolkit in Jonesport, Maine, in August, 1979:

Another example from the pianomaker Hornung estate in 1990

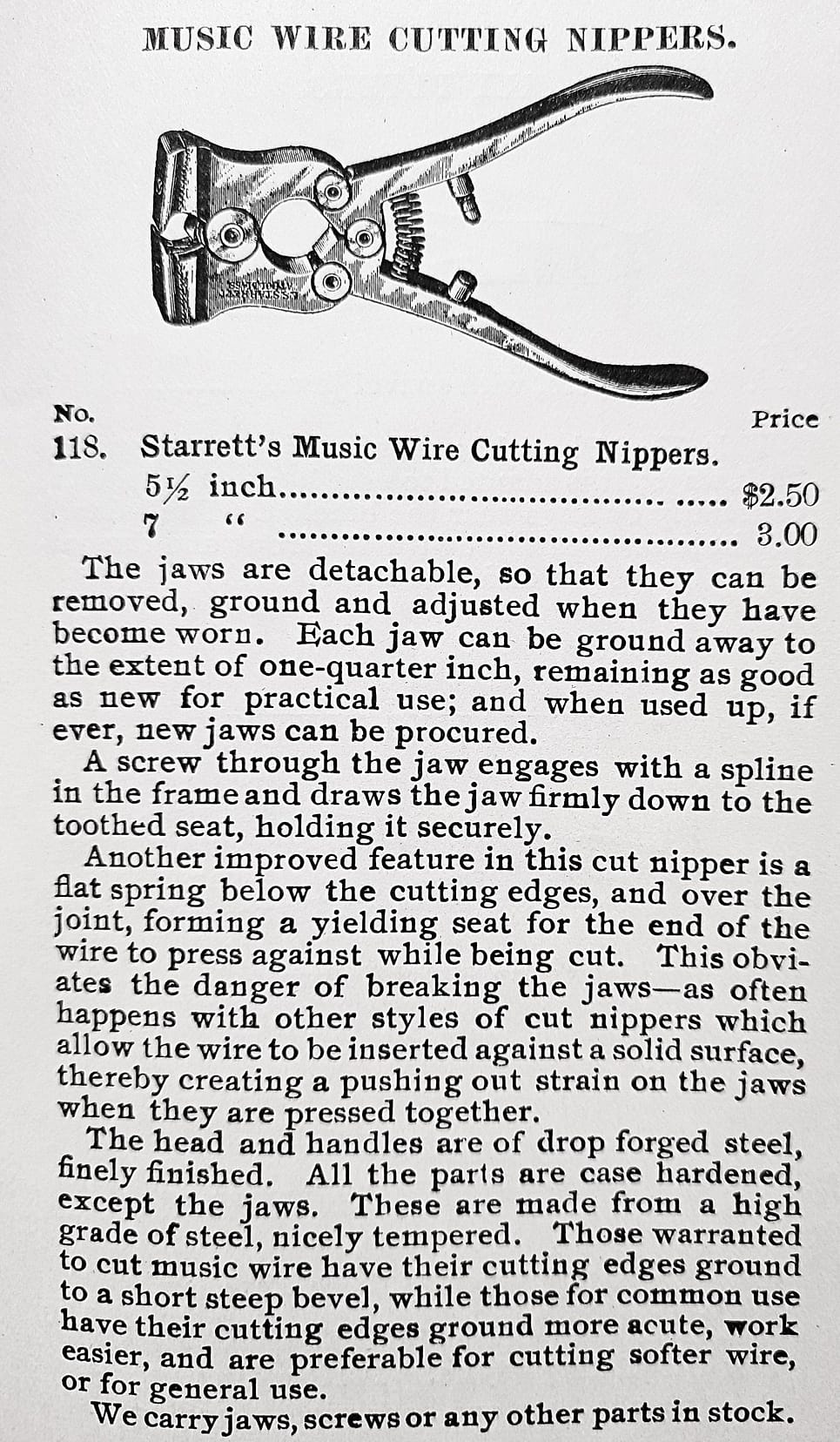

American Felt Co. 1911. Starrett music wire cutters, from Lang/ L&.H 1914 catalogue. These pliers are still available today from Starrett. Starrett also makes a music wire gauge, and a portable bottle jack, used to support the pinblock when stringing grand pianos.

Hall’s music wire cutters, as manufactured by Utica Tools. Hall’s cutting nippers with close view of patents, May 1867 to Jan. 1890. These were commonly used by tuners in the late 19th century and it is obvious that the Starrett design, which came later, was derived to a significant extent from the design features of these early compound action pliers.

Hall’s patent compound action plier, in music wire variant. H. S. catalog, 1885. H. S. catalog, 1885. Before Utica took over production of the Hall’s pliers, they were made by the Interchangeable Tool Co. of New York, N.Y., which was connected to the Hall family. This was a reference to the interchangeability of the pliers’ parts, a concept not fully taken for granted in the 1860s. Extra jaws were available, as they would sometimes break under very heavy compression. Screws would also work loose, and many of these are found with one or more replaced screws. I’ve cobbled together a few of these broken pliers, dealing with flying parts resulting from the strong internal butterfly spring. Experience has shown me that they are not fully interchangeable: a small amount of hand finishing was done to every set of pliers.

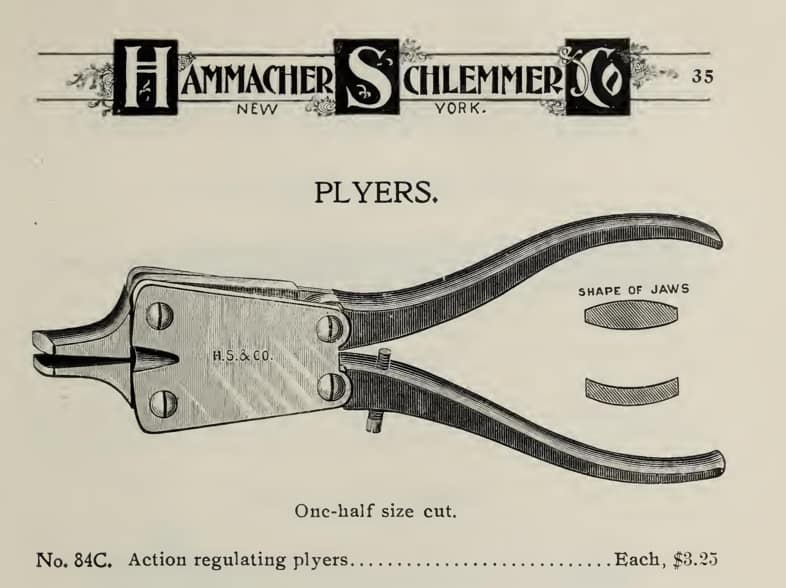

Hammacher Schlemmer Action Regulating Pliers, compound action, based on Utica Pliers. From H.S. 1903 Catalogue.

Early Key Easing pliers. English. An early type of key easing pliers, similar to an illustration in Seiver’s “Il Pianoforte…” 1868. Box-joint design.

Combination parallel pliers and hammer head extractor, made in Germany. It was an early plier-type hammer extractor on the market, but this tool was not often offered in the catalogs. For uprights, but also works on grands. Parallel as far as piano pliers are concerned, means that the jaws are parallel at the width of a typical piano action part, such as a damper head or action flange. Inventor Franklin Hoover also authored two other patents in this website: the screw holder on the Miscellaneous page, and the voicing pliers on the Voicing Tools page.

Early type of Hammer Extracting Pliers, which fell into obsolescence by the 1920s. From Otto Higel, Toronto Piano Supply Catalogue, 1906.

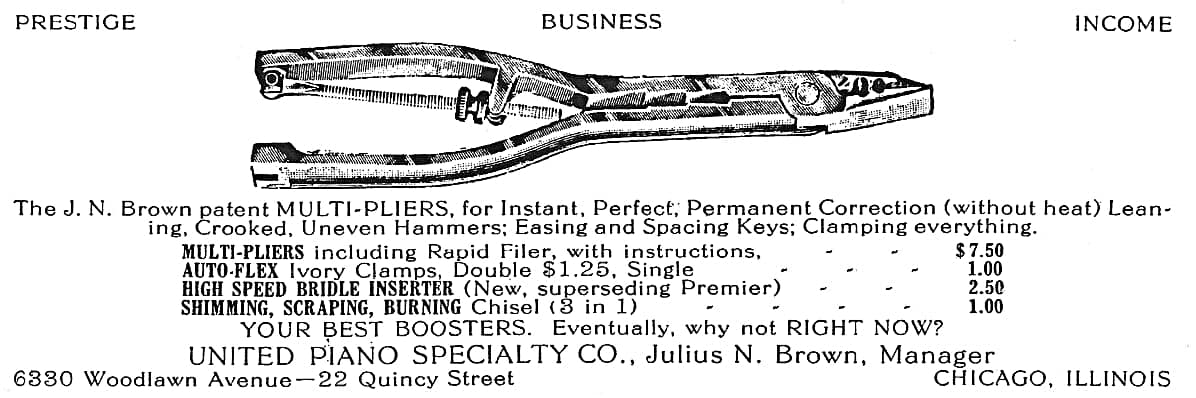

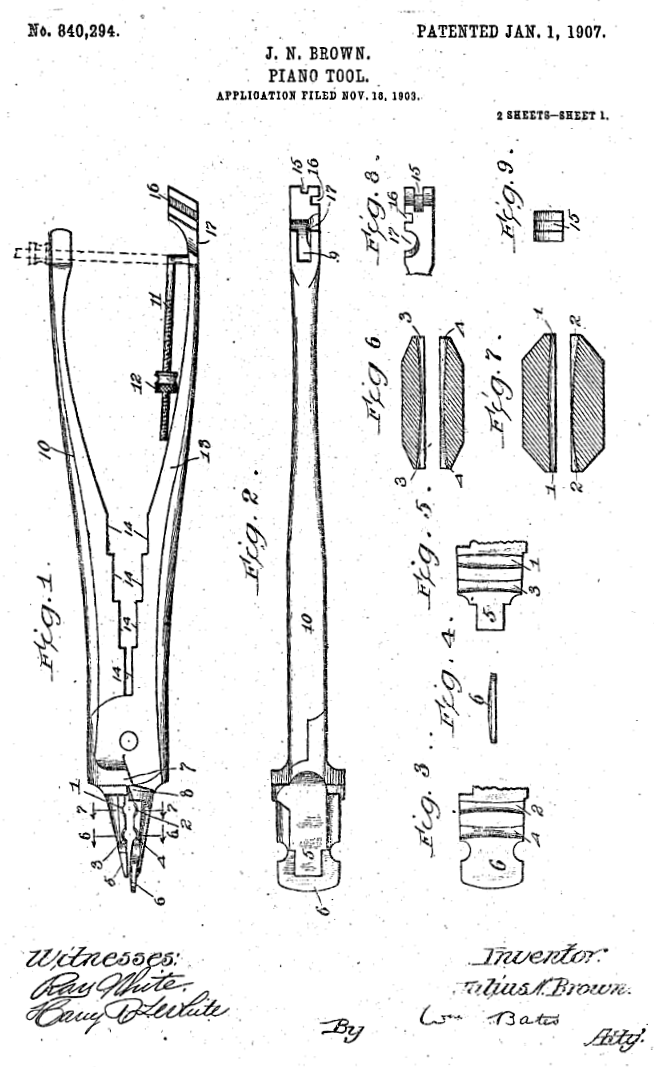

Julius N. Brown applied to patent his Multi-Pliers in 1903, and was granted a patent for them on 1 January, 1907. Brown’s Multi-Pliers were popular with piano technicians from c. 1910 to 1930, but they are not in use today.

This tool was sold by H. S. Co., Lyon and Healy, and Tuner’s Supply in the 1920s. At $7.50, these were expensive pliers indeed. Lyon and Healy, 1926. I’ve been around the piano business long enough to see various ideas come and go. This looks like one of them. It’s because the notion of bending maple shanks cold makes me uncomfortable; using heat and steam to bend wood is more standard practice. Brown’s combination pliers are a substantial and well made nickel plated tool, however

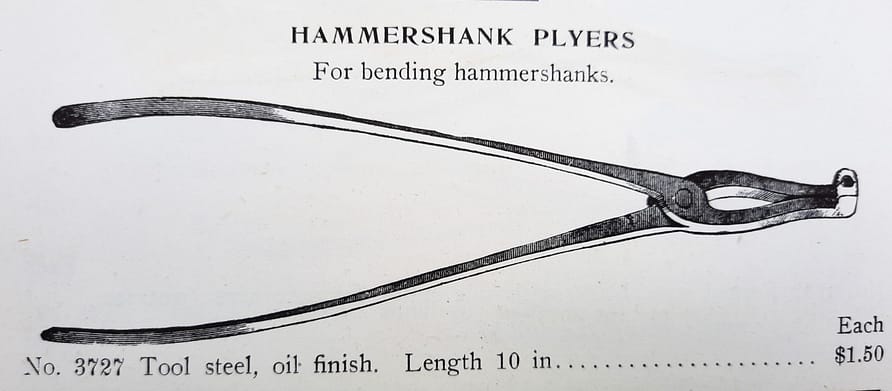

“HO TUNER BOYS,” Julius Brown, specialized pliers for bending maple piano hammershanks cold. Tuners Journal, December, 1924. Because $7.50 for a set of Multi-pliers was a lot of money in the early 1920s, a number of piano tuners asked Julius Brown to make pliers specialized for bending hammershanks cold, only–at a lower price. In 1924, Brown consented, and made a simplified version of his pliers for $3.75. I will leave it to you to assess how Julius felt about this, based on his salutation in this advertisement.

Hale advertisement for their combination pliers in the Piano Technician’s Journal in 1986. Clearly, the writers of this ad were not very aware of their end readers, who would have been a mix of older technicians who entered the field shortly after WWII, and the first wave of baby boomers, born between 1946 and 1953. Many boomers entered the piano technology field between 1970 and 1975, and, as a group, were intent on raising the general standard of piano work within the profession. By 1986, many of these folks had become established, and were gaining entry into the closely held institutions, venues, and private work indicative of a burgeoning dominance within the piano technology field. Pulling off a “piano caper” would not have appealed, generally, to this emerging group of boomers, but was more in line with the orientation of some of the older technicians, certainly not all of them however.

Frankly, I was surprised to learn that Hale plier-type hammer extracting tool shown below was developed as early as circa 1948-1950.

Letterhead pattern, from Hale 1953 Catalogue. The market for this sort of thing ended by aroundHale advertisement for their combination pliers in the Piano Technician’s Journal in 1986. Clearly, the writers of this ad were not very aware of their end readers, who would have been a mix of older technicians who entered the field shortly after WWII, and the first wave of baby boomers, born between 1946 and 1953. Many boomers entered the piano technology field between 1970 and 1975, and, as a group, were intent on raising the general standard of piano work within the profession. By 1986, many of these folks had become established, and were gaining entry into the closely held institutions, venues, and private work indicative of a burgeoning dominance within the piano technology field. Pulling off a “piano caper” would not have appealed, generally, to this emerging group of boomers, but was more in line with the orientation of some of the older technicians, certainly not all of them howeverFrankly, I was surprised to learn that Hale plier-type hammer extracting tool shown below was developed as early as circa 1948-1950.

Hale Plier Hammer Extractor, as advertised in the January, 1951 issue of “The Piano Technician.” The upright and grand hammer extractor functions worked pretty well on this tool. The knuckle and center pin extraction functions never gained much traction. Not having tried the center pin function, but being familiar with the other functions, I’d think that the center pin function would not be sufficiently precise. This multi-pliers design, developed by Hale, is still available from Baumgaertel in Germany and from piano suppliers in China.

The upright and grand hammer extractor functions worked pretty well on this tool. The knuckle and center pin extraction functions never gained much traction. Not having tried the center pin function, but being familiar with the other functions, I’d think that the center pin function would not be sufficiently precise. This multi-pliers design, developed by Hale, is still available from Baumgaertel in Germany and from piano suppliers in China.

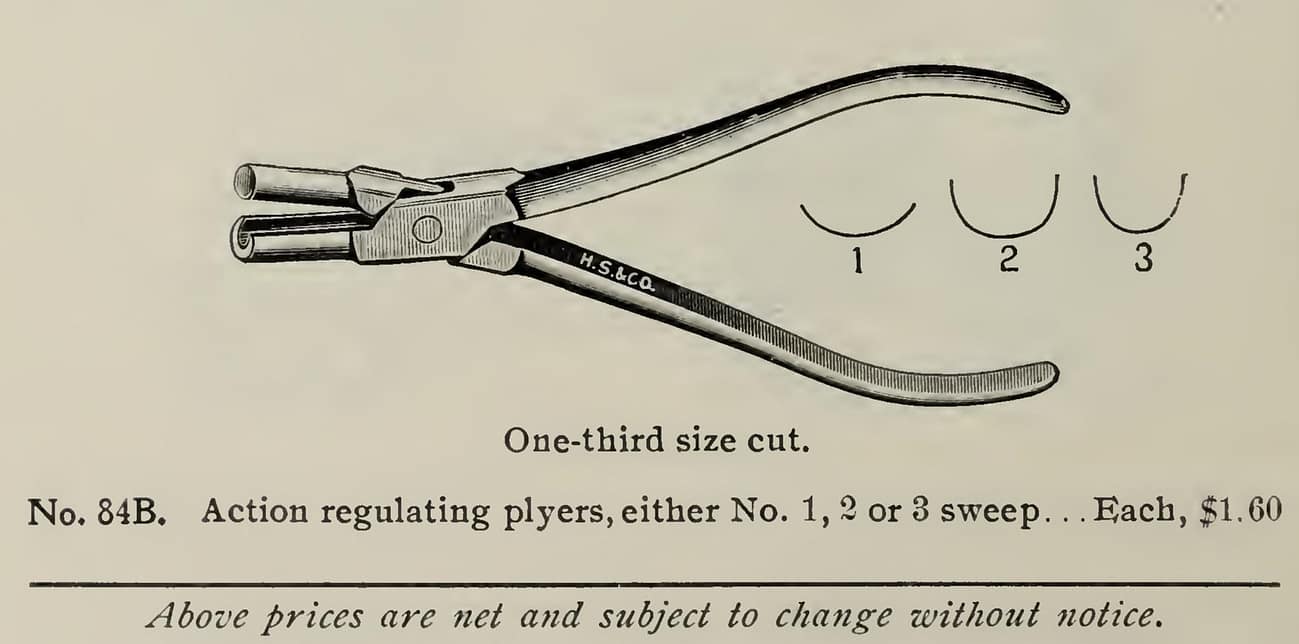

Erlandsen regulating pliers, from Hornung piano factory in 1990; Hammacher Schlemmer regulating pliers, no. 84 B1, also made by Erlandsen.

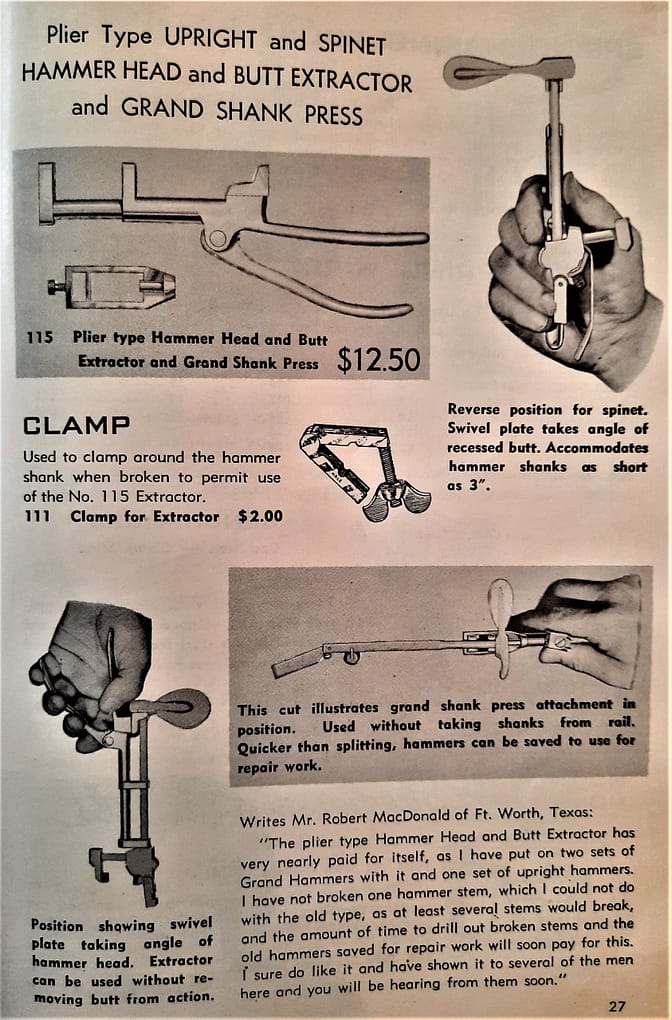

H.S. & Co. N.Y. Action Regulation Pliers, offered in 3 sweep patterns. From 1903 Catalogue. Apparently, the choice was important to piano workers at the time; to my knowledge, no current piano supply company offers several sweeps within one set of pliers. Stock number 84 B1 was the least sharp bend in the 1903 catalog.

Skillfully modified pliers.A group of standard production pliers, all made in upstate, Western tier, New York, which have been skillfully modified for specialized piano work applications, most likely in the 1930s. 1.Bridle tape inserter.

2.Altered needle nose–for contact at tip. Profile similar to modern felt compression pliers.

3.Center-pin extractor (lacking parallel action).

4.Key-easing pliers.

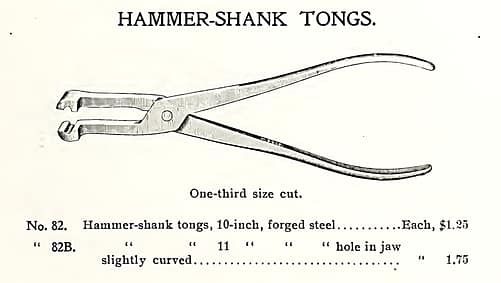

Boston Tuner’s Outfit hammershank bending pliers (Not Tuners Supply, Hale). Pliers would be heated with an alcohol lamp, sometimes with a wet rag added to create steam, and then clamped onto a hammershank and moved to correct hammer positioning.

It was possible to have specialized tools fabricated, from a machinist, ordered through a supply house. Schley catalogue, 1905.

Some dental extraction pliers have similar handles to the pliers on the left (above), and directly on the left, so these pliers may have been based on a set of them. The round jaw has a groove or notch, and the jaws do not touch when the pliers are closed. The H.S. pliers were made for spreading the loops in bridal wires to allow for easier installation and removal of the the bridal tape tips.

Plier position for illustration purposes only; lining up or straightening the bridal wires would be done at the base of the wire, near the wippen.