Extension Tuning Hammers

Carl (Charles) F. Mueller was born in Remscheid, Westphalia, Germany on 2 April 1861. Remscheid was a suburb of Solingen, Westphalia; Solingen was known for swordsmithing, knifemaking, and other fine metalworking since the Medieval Period. Remscheid, had its own edgetool and general toolmaking industry: Hilger und Sohn brace and bit makers were based in Remscheid, and E.C. Emmerich continues to manufacture tools in Remscheid. It was more than likely that young Charles got his early metalworking experience in Remscheid.

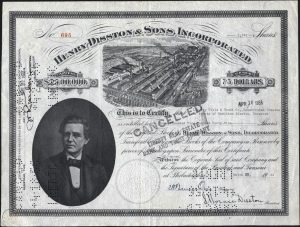

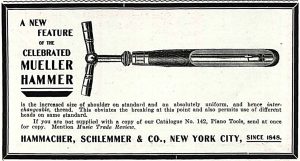

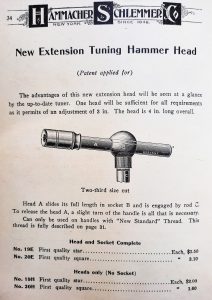

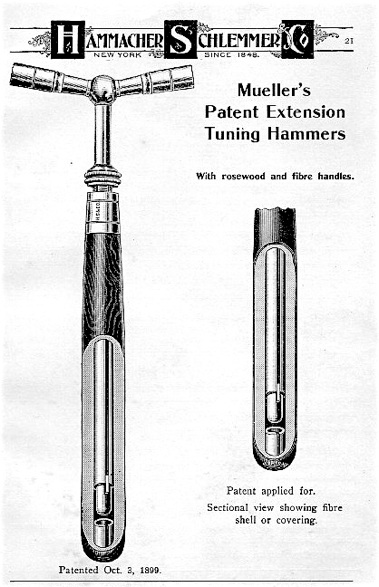

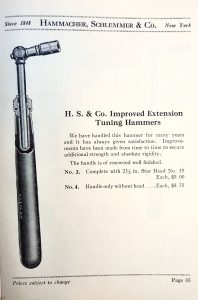

Mueller’s Extension Tuning Hammer, as featured in the Hammacher Schlemmer Pianomakers’ Tool Catalogue No. 142, published in 1903.

I never saw a Mueller hammer with an aluminum handle, but it is interesting to see that alternative materials were advanced to production, even back in 1903. The locking nut which compresses the collet to secure the adjustable shaft was not a new idea. That idea was introduced by Francis Hale in 1885.

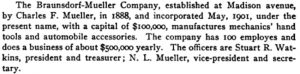

Braunsdorf & Mueller Co., as recorded in “The History of Union County New Jersey,” by Abraham Van Doren Honeyman, 1923.

In 1884, 23 year old Charles F. Mueller immigrated to the United States. At first, Mueller moved to Philadelphia and worked at the Henry Disston & Sons Saw Works for two years.

After settling in Elizabeth New Jersey, Mueller was able to participate within a sizable German immigrant community which had been established there. In 1886, Charles married J. Etta Shaw. Just 4 years after arriving, Mueller founded his tool making business.

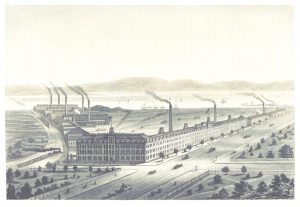

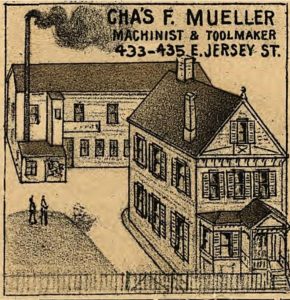

Charles Mueller, Machinist & Toolmaker. Inset from Landis & Hughs 1898 Bird’s Eye Map of Elizabeth, New Jersey.

Originally settled as “Elizabethtown” in 1676, Elizabeth served as the first capitol of New Jersey. In 1863, the Singer Sewing Machine established a large mass production factory in Elizabeth. At Singer’s pinnacle, the company employed 2,000 workers. The Electric Boat Company got their start building submarines in Elizabeth, in 1897. During the time of the 2020 U.S. Census, the population was 137,298.

Charles F. Mueller, “Manufacturer of Fine Tools,” 433 East Jersey Street, N.J. 1895 Elizabeth, N.J. City Directory.

By 1899, Charles F. Mueller had entered a partnership with Henry R. Braunsdorf, who was connected to the well-known hardware firm, Hammacher Schlemmer & Co. New York. Most likely, Braunsdorf introduced Mueller to H.S.& Co. Braunsdorf & Mueller were known for their wrenches, chisels, and general machinists’ tools. This article in “HARDWARE,” dated 10 April, 1899, described Charles F. Mueller as “a practical tool maker and an excellent temperer of steel.”

Charles F. Mueller lived very comfortably as co-owner of Braunsdorf & Mueller Co., which was reported to have as many as 100 employees. Charles and his family lived with a servant, and they owned their house since the 19th century, which would have been a residence that reflected Mueller’s elevated status.

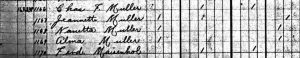

Charles F. Mueller in the 1900 U.S. Census, living at 433 East Jersey St., Elizabeth, N.J. with his family.

Mueller tuning hammer head, pre-patent, circa 1898: “E. [Erlandsen] Manufacturing Company.”

In the late 1890s, Hammacher Schemmer realized that they needed a new extension tuning hammer, in order to compete with Hale, and other makers, who were introducing hammers with a collet, tightened with a thumb screw. H.S. & Co. either commissioned Mueller to develop a hammer, or Mueller patented his tuning hammer on his own. In any case, despite the fact that Mueller was a manufacturing specialist, Hammacher Schlemmer & Co. turned to piano tool maker, Julius Erlandsen to manufacture the Mueller tuning hammer.

Charles F. Mueller was an important and influential figure in the German community within Elizabeth, N.J. 1917 Elizabeth City Directory.

The Mueller patent tuning hammer, as sold by Hammacher Schlemmer, had all the manufacturing details and hallmarks of Erlandsen tuning hammers: multiple double scribe marks, German silver ferrule, with brazed seam, same lettering stamps, and similar knurling on the adjustable shaft as the Erlandsen hammers. Also, the more common woodworking, mechanic, and machinist tools made by Braunsdorf & Mueller, bore little resemblance to the Hammacher Schlemmer piano tools made by Julius Erlandsen.

American Swiss File Co., took over the tool production of Braunsdorf & Mueller. From the “American Machinist,” 11 August, 1927.

Charles F. Mueller died in Elizabeth, New Jersey, on 30 November, 1919, and he was buried at Hillside Cemetery, in Union County, N.J. In 1927, the Braunsdorf Mueller Co. was sold to American Swiss File Co.

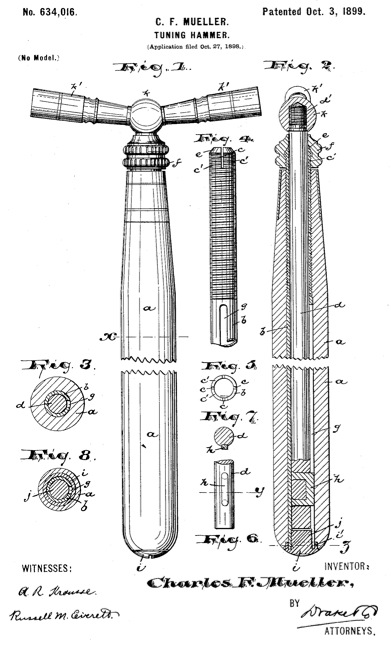

Here is Charles F. Mueller’s 3 October, 1899 tuning hammer patent:

Mueller had a 1907 patent for a screwdriver with a base other than a tang, in order to prevent splitting and loosening of the wood handle. Mueller also patented a bevel in 1902.

In all, Mueller filed 6 patents over a twenty year period, from 1899 to 1919.

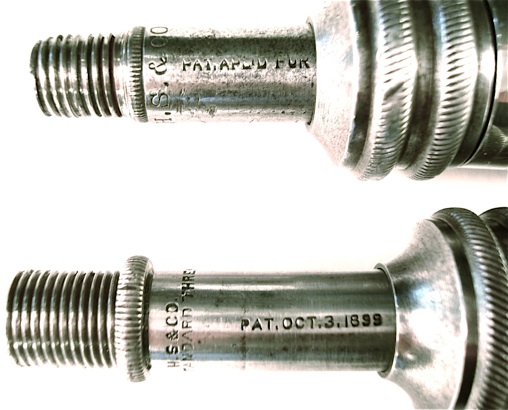

Another Mueller hammer made in 1898–99, “patent apl’d for”.

A comparison of the 1898-1899 Mueller and the post-1903 Mueller with “New Standard Thread”.

Both have a straight, and not tapered, thread with a friction mating/locking surface. The earlier version has a smaller diameter thread compatible with other Erlandsen hammers, and the later thread has a larger diameter, almost as large as the diameter of the shaft itself. A locking ring has been added to provide a secure fit.

H. S. Catalogue 1918, with optional fibre covering on handle.

“New Standard Thread” models.

MUELLER IMPROVED EXTENSION TUNING HAMMER

Handled by Hammacher Schlemmer & Co. Since 1891 with Much Success–Expert Tuners’ Suggestions Followed in Latest Improvements

Hammacher Schlemmer & Co., New York, describe a Mueller patent extension tuning hammer, shown in the accompanying illustration, as follows, in their catalogue:

These hammers have proven satisfactory in service since we first introduced them in the piano world in 1891. We have caused further improvements to be made, partly in accordance with suggestions made by expert tuners, and partly to secure increased mechanical strength and absolute rigidity, until we have evolved what we fully guarantee as an ideal tool. The absolute uniform, interchangeable thread has proven so strong and generally satisfactory that it has upon retained, with the added improvement that the end of the rod and the bottom of the recess in head are equally tapered to a perfect fit, which binds the head to the road almost as solidly as if the two were in one piece. This taper feature prevents the use of the old style heads on the new handle, but the old style heads may be tapered to fit at a minimal cost. The rod itself is one solid piece of of polished tool steel, the upper end being mushroomed out sufficiently to make the knurled overhang which supplies the tapering fit (mentioned above) for the head.

These improved hammers are fitted with a new locking device which grips the rod and handle so tightly that they become as rigid as one piece of solid steel A threaded steel tube about 3 1/2 inches long, made with two slots on opposite sides, is secured firmly to the handle. Two tapering blocks slide into these slots and are almost attached to the knurled nut, which, when screwed over the threaded tube, forces the blocks into tapered slots securely gripping the rod at any point desired. One of the tapering blocks slides in a keyway which runs almost the entire length of the rod, preventing the road from turning and assuring absolute rigidity when locked.

The handles are made of vulcanized fibre (either black or red). The characteristics of vulcanized fibre are such that it makes an ideal tuning hammer handle. It has the consistency of horn, great strength, is tough and durable, and improves with age, and it does not warp or shrink, it is obviously a handle far superior to one made of wood.

The head, rod, knurled nut with sliding blocks and the threaded tube are all made of the highest quality of tool steel, and the complete hammer is finely finished and polished. The cut illustrates the shape and style of the tool complete, also showing exact details of the keyway, knurled nut with sliding blocks, and threaded tube, as well as the tapered fit of the head to the rod.

Three Mueller ‘Improved’ Extension Tuning Hammers. These were made around the WW1 era, and through the 1930s; the one on the bottom is an earlier version, the same as the illustration in the article above.

Three Mueller ‘Improved’ Extension Tuning Hammers.

Oct., 3 1899, not 1888.

There are three different years given for the Mueller introduction/patent: 1891 in the Music Trades Review, Oct. 3, 1888 as inscribed on this hammer (I’m not sure if this is a mistake–it does not look like an over-impression of nines), and Oct. 3, 1899, the actual patent date. This is the earlier version with two tapering blocks as described in the above article:

Historical inaccuracies were common in the U.S. trade catalogues, even when it pertained to their own history. Apparently, there were/are no history majors on staff!

Here is the hammer in the 1925 catalogue. The reference to Mueller was omitted, which made sense, because it was not very similar to the classic original Mueller hammer.

Shown below is a later version, which has a larger adjustment nut, and only one tapered wedge that works on a flat part of the shaft visible in this photo. It was made by Julius Erlandsen through the 1930s, and as late as 1940. Both versions securely lock down the shaft in a positive manner.

The inscription was overstruck.

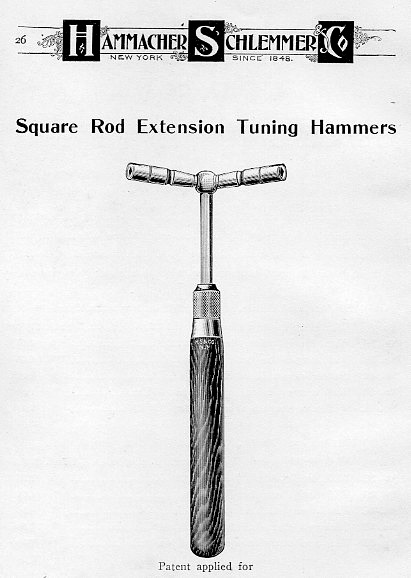

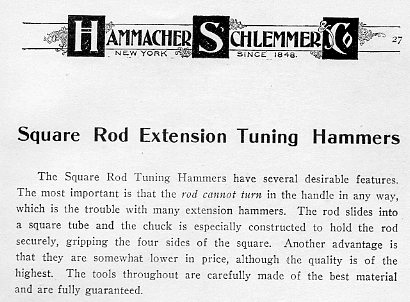

H.S. (Erlandsen) Square Rod Extension Tuning Hammer

The square shaft never rotates. I’ve not seen this in other tuning hammers; it works. 1918 H.S. catalogue.

H. S. tuning hammer, short version, with square shaft, “patent pending,” and New Standard Thread.

Advertisement from Hammacher Schlemmer for their Square Rod Tuning Hammer, and Pin Polisher. “Music Trade Review,” 1906.

1918 catalogue entry.

This elegant idea, developed by Julius Erlandsen, provided a tuning hammer head with tip that was adjustable by screwing and unscrewing the hammer shaft bearing against it. Erlandsen’s concept was copied by piano tool maker Richard Reynolds in London, England; many Erlandsen tools were imported to Great Britain, one of which served as an example for Reynolds.

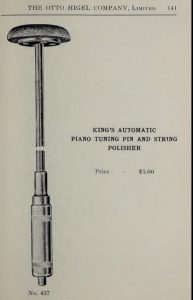

King’s Piano Tuning Pin Polisher, as advertised in the Otto Higel, Toronto Piano Supply Catalogue of 1906.