© 2024 – Martin Shepherd Piano Service Using the text, research, or images on this website without permission on an ebay auction or any other site is a violation of federal law in most countries.

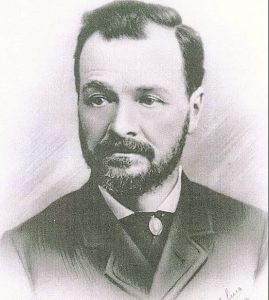

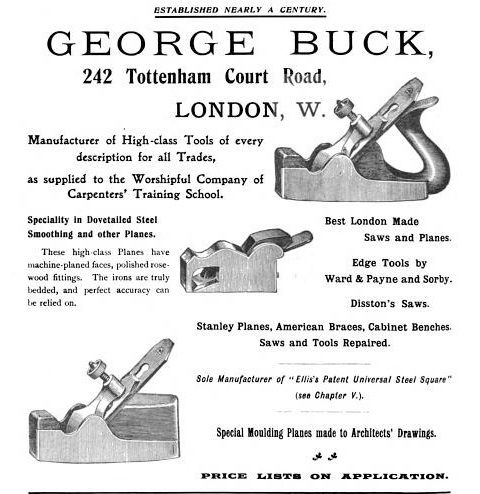

GEORGE BUCK tool supplier to the piano trade as well as others.

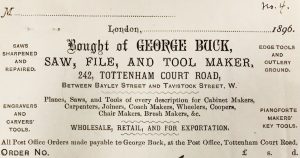

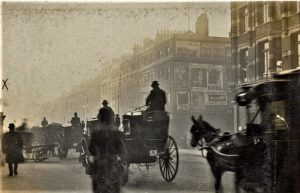

George Buck’s Tool Warehouse, 242 Tottenham Court Road, circa 1890. Left window: “Pianoforte Makers; Carpenters; Coach Makers & Engineer’s Tools.”

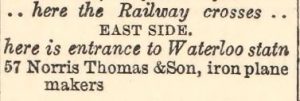

Norris-made Buck planes, c. 1908.

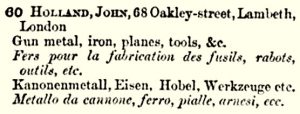

George Buck ad in “Modern Practical Joinery” by George Ellis, 1908. They offered bow drills, planes, tuning, voicing, and regulating tools to the piano trade. Specialized Buck piano tools can be found throughout this website, however, this page is focused on Buck mitre planes. For planes, George Buck carried the revered Norris line, but they put their own attractive mark on their tool merchandise. Buck has carried other infill plane makes during their long tenure in business, including Towell, Spiers, Holland, Slater, and Miller.

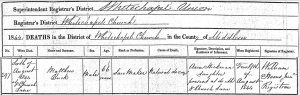

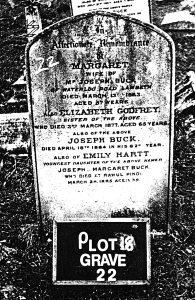

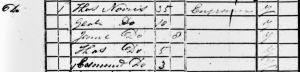

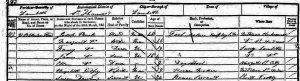

Matthew Buck (1776-1844)

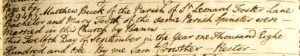

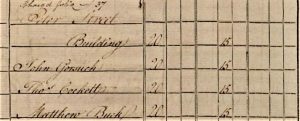

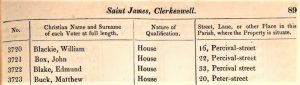

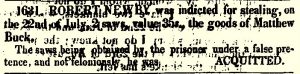

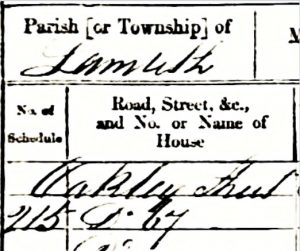

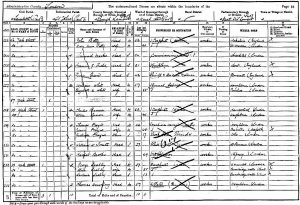

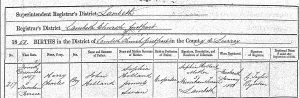

George Buck was born 30 October, 1805 to Matthew Buck (1776-1844) and Mary Tooth (1778-1810). Matthew Buck was a saw and filemaker who worked out of 22 Peter Street, Clerkenwell from before 1807, until after 1833.

Matthew Buck was Baptized 8 November, 1776, at the Cathedral of Saint Peter, in Sheffield, York, England. Sheffield was where Matthew Buck likely learned the metalwork necessary to make saws and files.

Before 1807, Matthew Buck lived on Eagle Court, which was several blocks East of Peter St. in Clerkenwell. Peter St., Clerkenwell no longer exists.

Matthew Buck, 22 Peter St. Clerkenwell, was listed under “Saw Makers,” in the 1825-6 Pigot’s London Street Directory.

The Bucks: A Family Affair

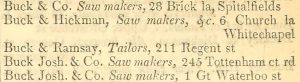

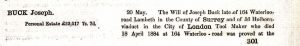

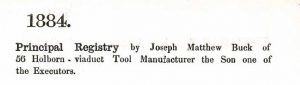

The Buck extended family became a large tool dynasty with three separate businesses, two of which continue to trade into the 21st century. A couple of of George’s siblings also started major tool shops: Joseph Buck (1802-1884), whose business became Buck and Ryan, and Ann Buck (1807-1895), who married John Hickman Sr. (1806-1847), and they established Buck & Hickman in 1832. In their early years, these businesses were quite intertwined.

“I. Buck” (Joseph, 11 July, 1802-18 April, 1884), at 1 Great Waterloo Street, Lambeth, in the 1825 London Trade Directory.

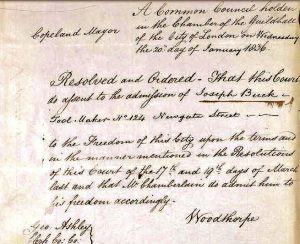

The 1825 London Trade Directory would have been sent to print in the fall of 1824, when George’s older brother, Joseph Buck was only 22 years old. Clearly, Joseph had access to some start up money. Joseph expanded to other addresses in just a few short years: 1 Gibson St. Lambeth, 1826; 245 Tottenham Court Road, 1831; 124 Newgate St., London City, 1834.

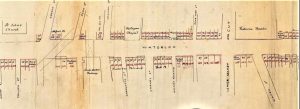

1 Gibson Street and 1 Great Waterloo Street were either very close to each other, or they were indeed the same location. The Royal Coburg Theatre (est.1818), later renamed the Victoria Theatre (c.1833), was listed as across Waterloo Rd. from the J. Buck warehouse in later directories, circa 1843-1890. Various street numbers on Waterloo St./Rd. were renumbering rather than actual moves: 1 Great Waterloo St./1 Gibson St. (1824-1843); 91 Waterloo Rd. (1844-1863); 164 Waterloo Rd. (1867-1893).

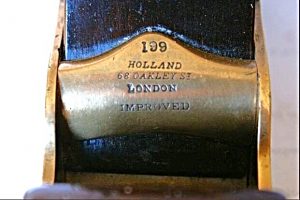

Oakley Street ran into Gibson Street. 68 Oakley Street was planemaker John Holland’s address from 1861 to 1871. This proximity likely fostered a working relationship between John Holland and Joseph Buck.

Street numbers on Waterloo Rd./St. were reconfigured rather than Joseph Buck moving the warehouse.

Waterloo St. Renumbering Plan, 1863, showing 164 Waterloo St., Joseph Buck Tool Warehouse. From Lambeth Archives.

1893 was the latest Buck address on Waterloo Rd. that I have found to date.

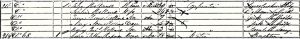

Joseph Buck declared his profession as a “Tool Maker, [who] employs 6 men,” at 91 Waterloo Road, Lambeth, in the 1851 U.K. census.

Ambition and drive were qualities that Joseph Buck possessed in spades. Joseph provided the initiative that established the Buck tool dynasty, which still trades today.

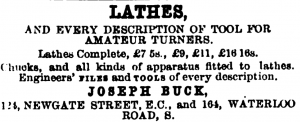

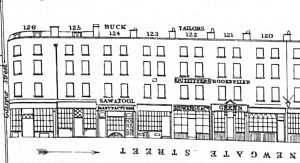

Joseph Buck traded in tools from 124 Newgate St. from 1834 until 1872, and he also sold lathes from that location. Lathes were very much in vogue for the “English gentleman woodworker” of the 19th century.

Joseph Buck 124 Newgate St., “Saw & Tool Munfacturers.” From Tallis’ “Street Views of London, 1838-1840.”

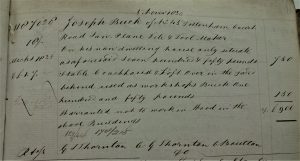

Before George Buck was listed as proprietor of the business at 245 Tottenham Court Road circa 1838, that address was under the auspices of his older brother, Joseph Buck. A Sun Fire Insurance Policy record from 5 November, 1834 (policy #1187028) revealed business owner “Joseph Buck of No. 245 Tottenham Court Road, Saw, Plane, File and Tool Maker.”

The main building and residence at 245 Tottenham Court Road was insured for £750. “Stable, coach house, and loft in the yard behind used as workshops. Brick £150. Warranted not to work in wood in the above buildings.”

Sun Insurance Company must have had a lot of power, which enabled them to write a deal like this.

A later Sun Insurance document from the same policy, referred to the business as “J. Buck, now George Buck of 245 Tottenham Court Road,” on 20 September, 1854. Even earlier, the 1832 Robson’s London Street directory listed both “Joseph and George Buck” at 245 Tottenham Court Road. Information for the 1832 Robson’s directory would have been taken in the Fall of 1831.

28 Brick Lane, Spitalfields may have been the actual saw making facility long searched for. This is the earliest document for Buck at 245 Tottenham Court Road that I have found to date.

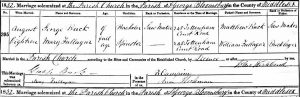

George and Mary were living together at 245 Tottenham Court Road, with their third child, more than 11 years before their marriage to each other.

At the time of the 1851 census, George and Mary Buck and their children were living in the housing quarters above the tool warehouse which was on the ground floor.

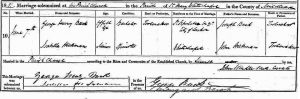

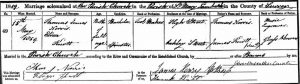

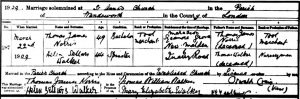

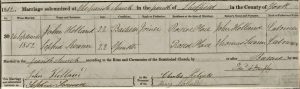

George Buck marriage to Mary Fullagar, 18 August, 1852. William Fullagar also lived at 245 Tot. Ct. Rd.

Typical of the mid-19th century, George Buck had a large family: George married Mary Fullagar and they had at least nine children. Or more accurately, George and Mary had a lot of children, then they got married.

George Buck and Mary Fullagar stated that they were “Of full age” in their 1852 marriage document.

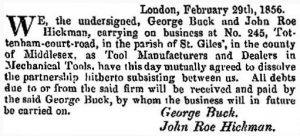

Dissolution of a second short-lived partnership: between George Buck and John Roe Hickman Jr. (1829-1904) From the London Gazette, 29 February, 1856.

Not to be confusing, George Henry Buck (1825-1891), son of Joseph, married his first cousin, Isabella Hickman. George Henry took over the business of Richard Nelson at 122 Edgeware Road circa 1850. In around 1893, George Ryan, a manager for George Henry since 1870, bought the business and it became Ryan & Buck. By 1910 the name was switched to Buck & Ryan. The Joseph Buck company, however, continued to trade independently until liquidation in 1922.

John Roe Hickman Sr. was a printer by trade.

George Henry and Isabella had at least six children. Both fathers declared their profession as “Toolmakers.” in this marriage document.

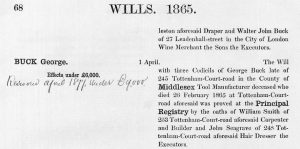

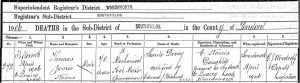

On 26 February, 1865, George Buck passed away at age 59. Many of the best years for George Buck’s business were still ahead of them, and their successors actively maintained the tool business into the 1980s.

It was George Buck’s tool warehouse, which was most closely associated with fine infill planes and piano tools from 1838 to World War One. Joseph Buck, however, did sell Towell planes in the 1830s and ’40s, and Buck & Ryan sold some Norris planes in the 1920s and ’30s.

Proprietary stamps for “BUCK” metal planes rarely included a first initial after 1850 or so. This differed from items marked specifically “G. BUCK,” such as bow drill stocks, saws, piano tools, chisels, braces, and wooden planes. Since a fair amount of capitol was tied up with metal infill planes, it would be a reasonable assumption that all three Buck businesses participated in selling these products by pooling their money.

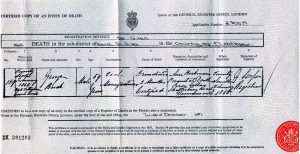

George Buck, death certificate. Died 26 February, 1865, from bronchitis. Ann Hickman present at death.

£23,000 in 1884 equals about $3,500,000 in today’s dollars. On average, businesses which sold tools as a concerted and organized effort, along with making tools, or dealers who traded in tools exclusive from making them, did better financially than those who primarily focused on making tools.

£65,847 in 1904 would be more than $10,000,000 in today’s dollars.

For comparison, Sheffield edgetool maker William Butcher died with a fortune of £100,000 in 1870. Scottish-born steel magnate Andrew Carnegie amassed a fortune of $380,000,000 or $309 Billion in today’s currency.

Joseph Buck’s 1912 Pianoforte and Organ Builders’ Tools

Joseph Buck’s 1912 Pianoforte and Organ Builders’ list offered 5 sizes of mitre planes, 3 types of thumb planes, and 2 sizes of panel planes. All of the mitre planes and at least two out of three of the thumb planes would have been made by Norris, because that was where Buck was sourcing most of his infill planes just before The Great War. What planes were included, as well as the planes that were omitted, provide insight into which actual planes were in demand for purchase within the piano industry. Following logically, this gave an indication around what planes were used more and what was used less. No smooth planes were included in this list for pianomakers, which could indicate that bevel up planes were used in common practice for a wider range of tasks, including at least some smoothing.

Buck and piano tools: Music Trades Directory 1912. I have a signed George Buck tuning hammer with a previous mark filed off, quite probably R. Reynolds, who provided Buck with most of his specialized piano tools.

George Buck’s Tool Warehouse, 242 Tottenham Court Road, circa 1890. Left window: “Pianoforte Makers; Carpenters; Coach Makers & Engineer’s Tools.”

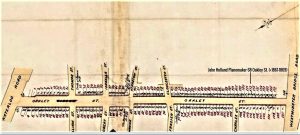

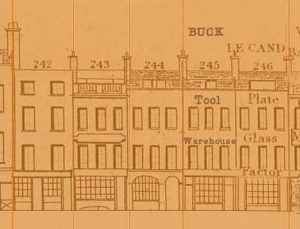

245 Tottenham Court Road, from John Tallis’ Street View Map of London circa 1838-1840. Image from the Museum of London.

Change of addresses may have been renumbering rather than actual moves. Buck was trading at no. 245 before 1840 when information was taken for the map.

The Bucks as Saw Makers

All census information, except the address were obtained by the resident’s response to the census takers’ questions. Are they the last word in defining the vocation of these planemakers? Not necessarily, but given the relative dearth of information for these individuals, it’s one of the best references we have under the circumstances. The working classes and skilled craftspeople of the 19th century and earlier were not generally people of letters, so there is less information to work with than the more academically educated classes. They were smart in other ways.

Many early wills were signed with an “X” not unlike this example.

Here is an example of this census reporting issue. George Buck was known as a tool dealer rather than a maker, but in 1861, he described his business as a “Saw Manufacturer.” After all, George’s father Matthew made saws, and George must have possessed the know-how to make saws, at the least.

Another large tool dealer, Moseley, also described their business as a manufacturer of tools, and for a number of years, they had a horse mill at the rear of their premises. I could find no direct evidence to date of an in-house shop at 245 Tottenham Court Road making tools from scratch. George and Joseph Buck, however did have workshop space behind the 245 Tottenham Court Road in three areas: a stable, coach house, and loft. That would have been enough combined space to make tools, but it was unclear if Buck actually made tools, and ignored the restrictions around working in wood that were mandated by the Sun Insurance Company. Perhaps George Buck owned an off-premises saw making shop we do not know about.

Consistently during George Buck’s life, and after his death, the Buck business was listed as a saw maker. Multiple sources for this lends credibility that the G. Buck firm actually did make saws, and possibly some other tools such as files. On the other hand, they could have been sold on the idea of being recognized as a maker of tools. At various times, all of the Buck firms listed their business under “saw, file, and plane makers.” This included Joseph Buck, Buck & Hickman, and George Henry Buck. Patriarch, saw and filemaker Matthew Buck (1776-1844) must have exerted a lifetime influence on his children.

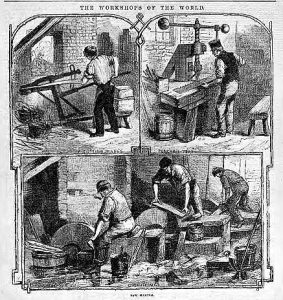

Illustrations showed phases of saw making: cutting, grinding, and punching teeth with a fly press. Not included was a furnace.

George Buck’s siblings also identified themselves as “Saw and Toolmakers.”

![]() Iron planemaker Richard Bywater, P.O. Directory 1805; 72 Tottenham Court Road (<1794-1807); 218 Tot. Ct. Rd. (1808-1814>). Much earlier, but worth inclusion.

Iron planemaker Richard Bywater, P.O. Directory 1805; 72 Tottenham Court Road (<1794-1807); 218 Tot. Ct. Rd. (1808-1814>). Much earlier, but worth inclusion.

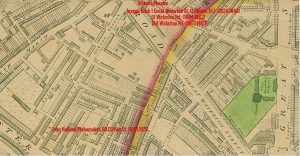

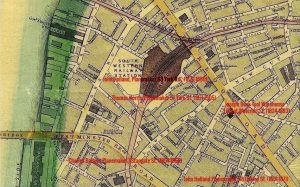

Section of a detailed London map, by the Ordnance Survey in 1893-96. George Buck’s tool warerooms at 245, 247, 242 Tottenham Ct. Rd (1831-1930; 21 Goodge St. 1938-80>), and his neighbors in allied trades during the 1860s-90s: J. & J. Goddard, piano supplies, 68 Tottenham Court Road (1842-1968); Richard Reynolds, piano ironmonger/toolsmith, 4 Upper Rathbone Place (<1880-1895; in Hammersmith to 1940); George Kerr, planemaker, 36 Store St. Bedford Square (c. 1864-65)

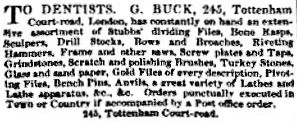

From the establishment of his business in 1831, George Buck supplied a wide range of trades and professions. These dental instruments make me appreciate living in the 21st century.

Map section shows the following: Joseph Buck, brother of George Buck, b 1802. planemaker and dealer, 164 Waterloo Rd. (1824-1893); Charles Badger, iron planemaker, 1 Stangate St. (1854-68) 93 York Rd. (1868-70); John Holland, planemaker, 68 Oakley St. (1861-71), 93 York Rd. 1870-90); Thomas Norris tool and planemaker 57 York St. (<1871-1905).

Buck/Towell

This Towell mitre plane has an iron made by I.&H. Sorby, as do most Towell mitre planes.

A minority of Towell mitre planes can be found with Ward, and other makers’ irons, however. All of the irons would not have a nib; when the nib came into use by Spiers, Moon, and Cox in the late 1840s, Towell did not adopt it. Towell and his son, Robert Jr., would continue to make planes as late as 1863.

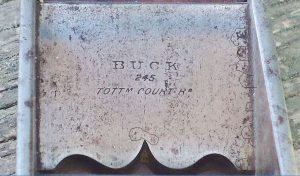

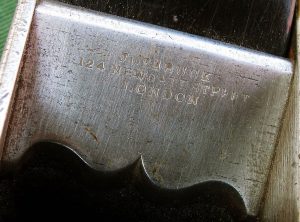

Buck (Towell) mitre plane, stamped 245 Tottenham Court Road., dating from the early 1830s and through the 1850s. By 1851, George Buck’s business had grown to the point where 8 men were employed there, as reported in the UK census. 245 Tottenham Ct. Rd.was George Buck’s address from 1838 to 1861. The “BUCK 245 TOTTENHAM Ct. Rd.” stamp used the same lettering font/format as the “Rt. TOWELL LONDON” stamps. It makes for a strong indication that Robert Towell himself applied these stamps in his workshop. For more information on Robert Towell, see the page on “Early English Mitre Planes, Part II” This plane is also very similar, if not identical to the one used to plane spotted metal for organ pipes at G. Fincham Organ Builders.

Dual marked plane: Buck on bridge and Towell on rear infill. Someone lost their patience with this tool, and filed the mouth open. Photo by Robert Leach. From website http://www.oldhandtools.co.uk/blog/english-mitre-planes.

10″ Towell mitre plane, with 2″ Ward iron; stamped on bridge, TOWELL LONDON, and on front infill, BUCK 245 Tottenham Court Road. Formerly Bob Funnel collection. Photo from D. Stanley Auctions, lot 266, September, 2014.

Mitre plane bridge made by Robert Towell, but marked Joseph Buck 124 Newgate St., London (also 91 Waterloo Rd.., Lambeth). Photo from Hans Brunner

Here is another mitre plane, 10″ long, with a 1 7/8″ Ward & Payne cutting iron, stamped Joseph Buck 124 Newgate St., London. With a Ward iron instead of I.& H. Sorby, and the placement of dovetails on either side of the mouth, rather than a tonge and groove joint, I am inclined to think this plane was made a little later, circa 1840s and 1850s.

Also, with a long iron, barely used. This example was found in New England (after decades of storage), and never in a dealer sale or auction, It was likely brought to America by an English immigrant in the mid-19th century.

Sole of J. Buck mitre plane, showing tight mouth. Dovetails were placed on either side of the mouth, instead of the usual tongue and groove joint. After almost 200 years, this has not posed a problem.

© 2023 – Martin Shepherd Piano Service Using the text, research, or images on this website without permission on an ebay auction or any other site is a violation of federal law in most countries.

Buck/Holland

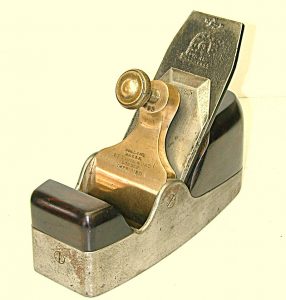

The following three Buck mitre planes share similar fundamental aspects as well as many details. Considering the similarities of these three Buck mitre planes, it’s apparent they were made by the same maker, and I believe that was John Holland (1830-1912).

This is an earlier example of a Holland/Buck mitre plane, 245 Tottenham Court Road, probably circa 1857-66; the address was actually 245-247 Tottenham Court Road from 1862 to 1866. In around 1857, John Holland moved to Lambeth along with his family. The stamp is otherwise the same as the other later Buck mitres (247 and 242), shown down the page, with similar features, including the convex bridge. The bridge is less convex than the later mitres, but it is still noticeable.

Almost invariably, these Buck/Holland mitre planes have snecked, or nibbed Ward & Payne irons. The earlier Towell mitre planes, in original condition, typically have I. Sorby irons, with no nib.

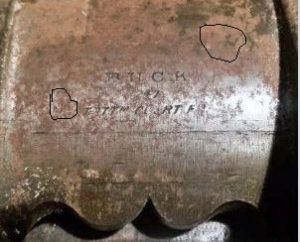

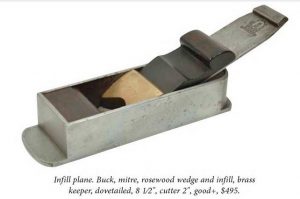

Holland/Buck mitre plane, 8 1/2 long, with 2″ nibbed Ward & Payne iron. 247 Tottenham Court Road (1867-1879).

Layout and construction of this Holland/Buck 247 mitre plane was essentially similar to other examples; the plane body was made shorter by decreasing the length of the toe in front of the mouth, as well as a shorter front infill. The width of the plane is full, and comparable to the other two Buck/Holland examples: 245 and 242 Tottenham Court Road, respectively.

Holland mitre plane, 242 Tottenham Court Road, marked and sold by Buck, (1880-1890). 10 1/4″ long with 2″ Ward & Payne nibbed iron.

Third Buck/Holland mitre plane, convex bridge, with Cupid’s bow. Buck, 242 Tottenham Court Road (1880-1890). It’s unusual to see many box mitre planes made after 1860, and more so to see a plane with a cupid’s bow bridge after the 1870s.

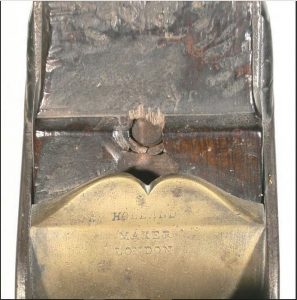

Dovetailed George Buck mitre plane, 242 Tottenham Court Road, London, post 1880, as Buck occupied 242 Tottenham Court Road from 1880 to 1930. Most likely made by John Holland. There is a very small set of J H initials up near the nib. Buck must have been strict about not revealing the makers of his planes.

Here are some similarities listed:

- Layout of dovetails: 2 dovetails in front of mouth; 3 dovetails behind mouth.

- Shape of heels: double bend, or two rounded corners.

- Shape of rear flanges (see photos).

- Very small mouths.

- Front and rear sole piece dovetailed together at mouth.

- Shape and moulding of front infills: medium length, with lip and concave shape below it.

- Profile of wedges (see photos).

- Style of cupid’s bow: cut uniformly near 90 degrees.

- Convex curvature of bridge–with varying amounts of curvature.

- Same species of rosewood: dark red Brazilian rosewood.

These Buck mitres are different in the following ways:

- Different shape for front flanges (see pictures).

- 245 Tottenham Court Rd. has a slightly curved bridge, while curvatures on 247 & 242 Tottenham Court Rd. are pronounced.

- Infills on 245 are screwed in at the toe and heel; 247 and 242 were pinned through the sidewalls.

“BUCK” marked bridge, with initials “J H” scratched in or acid etched. This is exactly the same photograph that was previously posted, when I had initially thought the plane was made by Norris. Some of the letters are now circled, most of which run along near the left cheek of the plane. Some markings have “JH” letters running together, sharing the left vertical line of the “H,” in a monogram. It must be where Thomas Norris got the idea for his “TN” monogram. Circa 1862 to 1866, when Mrs. G. Buck was at 245 and 247 Tottenham Court Road.

When John Holland would have made the Buck 245 Tottenham Court Road plane in the 1860s, he would have been just starting in his career. It makes sense that Holland would try to take credit for the plane, because most people starting out in a career have something to prove. That may be why the later Buck planes, that were unmistakably from the same maker, did not have such prominent markings. Subsequent mitre planes coming from John Holland, and rebadged as BUCK, more often than not, had identification relegated to “J H” initials on the cutting irons. If any at all.

Buck mitre planes, with similar construction and detail features as the 3 featured in this segment. l. 245 Tottenham Court Road; r. 247 Tottenham Court Road. From the collection of James Claussen.

In addition to the convex shape of the bridge, the cupid’s bows were not deeply cut as one would expect to generally see from Robert Towell. Cupid’s bows were identical for all 245, 247 and 242 Tottenham Court Road marked bridges shown on this page for comparison. Letters for “BUCK” are more spaced apart than Towell’s stamp, and the address is done with fine incuse letters with a slant, in Gothic. Holland/Buck used this stamp from the 1860s to ~1890, when Norris/Buck switched to “BUCK Tot. Court Rd.” in small upright Gothic letters. A variation of this post 1885–90 stamp read “BUCK Tottm. Ct. Rd.” These later stamps seem to be applied by the Buck the dealer, rather than the maker, as they are sometimes found not perfectly straight. The slanted Gothic lettering stamp was used during the tenure with Holland, from the late 245 Tottenham Court Road address, throughout the 247 Tot. Ct. Rd. period from 1867 to 1879, and into the 1880s at 242 Tot.Ct. Rd.

Convex bridge from Buck/Holland mitre plane, showing address of 247 Tottenham Court Road, circa 1867 to 1879. Note the same stamp format as well as an identical cupid’s bow to the two mitres shown here. Photo from internet source.

The Norris no. 11 bridge has similarities with the Buck mitres in question. Because of these similarities, Thomas Norris cannot be ruled out. In any case, there was a significant gap in time between production of the last Buck/Holland type mitres in the 1880s, and the introduction of the Norris no. 11 small box mitre circa 1914-1925. Only a few of these were made.

Considering that Buck bought in planes from Towell, Spiers, Slater, Holland, Miller, and Norris, which of these makers can be eliminated as the possible maker? Since the three Buck planes with a convex cupid’s bow bridge shown on this page were dovetailed, only Spiers, Holland, and Norris dovetailed their mitre planes. Towell dovetailed his planes as well, but his productive years (1810-1863 at the very latest) were too early for consideration here. These planes were made ~ 1860s to 1890. Miller did not make any mitre planes, and his planes were all cast in gunmetal. Slater made a modest number of cast iron mitre planes, appearing mostly unmarked, or rebadged, such as for Tyzack or Moseley. Buck sold rebadged Spiers planes, and four examples can be seen below. They do not appear to be different from Spiers signed planes in any way. This is to be expected, as it would be unlikely for a plane maker to sell their planes at a lower price, wholesale to the trade, with any special new designs or modifications unless required by the dealer.

Buck/Spiers

Early Spiers mitre plane marked “Buck 245 Tottenham Court Road.” Stewart Spiers sold many early planes to Buck, Moseley, Mathiesen, and Archer, as well as other dealers. Planes were either rebadged by the tool dealers, or by Spiers himself. Some early Spiers examples were never stamped with a mark at all. After 1880, Stewart Spiers apparently did not need to sell his products wholesale to the trade.

A similar 8″ Spiers mitre plane to the example above: with early style front infill, early lever cap screw, squared-off flanges, double bend in sidewalls at heel, rear flange (not exclusively a later feature for 8″ examples), side screws for attaching lever cap, and a relatively short neck on lever cap.

This Spiers mitre plane sold in the Martin Donnelly November 2020 Antique Tool Auction for $2,400. It looked to be in fine condition, with the only apparent issue being the bounce of the name stamp on the lever cap.

Buck (Spiers) mitre plane, c. 1870s. Standard Spiers design. Warman’s Price Guide, Clarence Blanchard, 2011.

This was among the last Spiers planes to be bought in and rebadged by a dealer. A few later examples can be found, having lever cap screws without cusps, but they are scarce.

Buck/Holland (continued)

Holland would be the remaining possible maker of these dovetailed mitre planes, other than Norris, and there’s a shortfall of Holland’s examples available for comparison. What makes the Holland/Buck type mitre planes unusual, is that they seem to be limited to the Buck dealer stamp, and do not appear elsewhere with the original planemaker’s stamp. Of course a maker-stamped mitre might show in the future, and if it does, it could give a more definitive answer as to who made all the Buck mitres with cupid’s bow and curved steel bridges, from the 1860s and into the 1880s. While these Buck mitres are rare, a fair number of this vintage and type have shown up over the years: there are more Holland/Buck mitre planes with the convex steel bridge than Holland-marked mitre planes with a gunmetal bridge. Enough Holland/Buck mitre planes were made that fitting numbers were necessary to keep all of the parts organized in the workshop.

In recent years, antique tool dealers and auctioneers have proffered their own assessment as to the identity of the maker of these mitre planes. Two tool dealers and one auctioneer advanced Norris as the likely maker, and one auctioneer proposed Holland. A rebadged Norris plane has a greater potential to achieve higher prices, so this evaluation may not be entirely objective.

A key differentiation between the Holland/Buck type mitre plane and the Norris No. 10 mitre plane is in their construction, which is hard to see in the Norris mitres because the sides and sole were both made of steel. In most of the Norris No. 10 mitre planes, there are 3 dovetails on each side: 1 dovetail in front of the mouth, and 2 dovetails behind the mouth (exceptions exist). In the Holland/Buck type mitre planes, there are 5 dovetails on each side: 2 dovetails in front of the mouth, and 3 dovetails behind the mouth. I have observed this 2-3 construction on 3 Holland/Buck type mitre planes in my collection, and the 1-2 construction on 5 Norris No. 10 mitre planes, also in my collection. In a definitive Holland mitre plane (formerly Max Ott collection) there are 5 dovetails on each side: 2 in front of the mouth, and 3 behind. Additionally, I have seen these same construction fundamentals in other similar mitre plane examples.

Bill Carter, a famous U.K. planemaker, who makes small mitre planes as a specialty, studied the historical English and Scottish planemakers in order to inform his own work as well as to satisfy his natural curiosity. From the beginning of his planemaking in the 1980s, Bill Carter made detailed drawings of antique planes, showing dimensions, bed angle, mouth construction, thicknesses, and dovetailing. In recent years, Bill Carter has made videos showing his work methods, including this one, where he revealed his archive of drawings of antique mitre planes. At 5:40, Bill Carter stated that he had observed a number of Norris mitre planes with 1 dovetail in front of the mouth, and 2 dovetails in back of the mouth.

Working years for Holland ranged from 1857 to 1907, which encompassed the time in the 1860s when the earlier plane was made. While Norris advertised that he was established in 1860, it was realistically more as a maker of wood planes and other joiners’ tools early on. Thomas Norris (1836-1906), described his profession in the 1861 UK census as a non-specific “Joiners’ tool maker,” then in the 1871 UK census as a “Tool maker;” and next in the 1881 UK census as a “Plane tool maker.” Finally, in 1890, Thomas J. Norris listed his specialty as an “Iron Plane Maker,” in the London City Directory. This does not mean that Thomas Norris did not make metal planes before 1890; it did suggest that before 1890, metal planes were not necessarily a primary focus for Thomas Norris.

Some Holland History

John Holland was born in Riby, Brocklesby Lincoln, which is near the South shore of the Humber estuary on the East coast. His parents were John and Mary Holland, and he was baptized on 4 July, 1830, in Riby. Today, Riby is a tiny hamlet of 129 inhabitants.

John Holland, “Shipwright,” 21, living as a boarder at 40 Potter Yard, Gainsborough, Lincolnshire. 1851 U.K. Census.

In comparison to Thomas Norris Sr.’s early generalized production, John Holland’s early specialization in metal planemaking was evident from extant early examples of his planes, and in historical documentation. During the 1850s, John Holland lived in the Sheffield area, which was a hotbed of innovation in metallurgy.

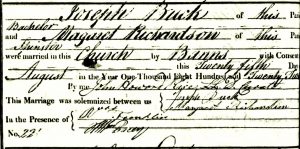

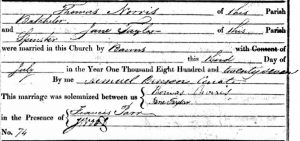

John Holland married Sophia Swann at the Cathedral of St. Peter & Paul, in Sheffield, on 26 September, 1852.

Sophia Swann (1830-1901<) was born in the hamlet of Dalham, Suffolk County. Sophia met John while she was working for the Wick family in Sheffield. John and Sophia had four children: James Henry, born 1853 in Sheffield, d. 1881 London; Mary Agnes, born 1856 in Sheffield-d.1943, Q4 N.W. Surrey; Harold Charles, born 1857 in Lambeth-d.1925 Battersea; Samuel Swann (1868 Lambeth-1951 Streatham, London).

John Holland, Sophia Swann, 4 year old James Henry, and 2 year old Mary Agnes first stayed at 40 Clerkenwell Green, in mid 1857, before relocating to Lambeth later that year.

Harry Charles Holland was born 4 December, 1857, and the Holland family was living at 5 Newnham Terrace, in Lambeth, 1 block south of 68 Oakley St.

Holland No. 199 Smooth plane, 68 Oakley St. London; Improved. As many as 6 hand stamps were involved in making this inscription.

John Holland. 68 Oakley Street, early recorded residence: before June, 1860. Financial report for Amalgamated Society of Carpenters & Joiners.

John Holland’s 68 Oakley St. address (<1860-1869) is marked on this map excerpt.

–Old numbers in black, new (1877) numbers in red. Gibson St. crossed out and replaced with Oakley St.

Holland wasted no time establishing his tool making business; he probably started tool making work in 1857, when he moved to Lambeth.

Holland’s description of his business underscored his initial involvement in iron and gunmetal planemaking. Searching for an apprentice 1864, John Holland posted the following ad in the Clerkenwell News: March 23, 1864:

![]() “Apprentice wanted to the Gun Metal, Iron Plane and Mechanical Tool Manufacturing; a premium required, Apply to Mr. J. Holland at 68 Oakley Street, Lambeth.”

“Apprentice wanted to the Gun Metal, Iron Plane and Mechanical Tool Manufacturing; a premium required, Apply to Mr. J. Holland at 68 Oakley Street, Lambeth.”

Christopher Gabriel (1746-1809) assigned serial numbers to his mitre planes, and likewise, John Holland gave serial numbers to his smoothing planes. Holland’s numbers ranged from 87 to 867 (subject to revision). Sometimes Holland would include his street address, and when he did, it can be observed that his lower serial numbers would show 68 Oakley St., and his later, higher serial numbered planes would show 93 York Rd., as would be expected.

Many of Holland’s other planes did not have numbers, for example, his mitre planes lacked them; with so few marked Holland mitres, they were probably considered unnecessary. Also, Holland left many of his planes unmarked, in order to be bought in by tool retailers and stamped with their own proprietary inscription. These planes would have been without numbers as well. Sometimes the initials “J.H.” would be stamped in a less prominent location, such as on the bed, or on the iron.

In the case of Smoother No. 213, a large “I.H.” was added into the casting underneath the rear infill. I would not have discovered this unless the rear infill had come unglued. Additionally, “Holland, London” was stamped into the underside of the bronze lever cap.

John Holland, 68 Oakley St., in The London Gazette, on 6 November, 1866. Gunmetal and iron, separate commodities.

In 1869, John Holland was listed in Kelly’s, Post Office and Harrod & Co., Trade Directory as a “Gun[metal] and Iron Plane Maker,”

1870 London P.O. Directory: “John Holland, Gunmetal & Iron Planemaker. 68 Oakley Street, Lambeth. S.E.”

Early on, John Holland concentrated on metal tools, and was even listed as a dealer in gunmetal stock in 1870.

Since John Holland took over established metal planemaker, Charles Badger’s workshop and tools at 93 York Rd. Lambeth in 1870, he would have been thoroughly prepared to produce infill planes during this early time period. By the time of the 1881 UK census, John Holland employed two men besides himself for his tool making enterprise.

Holland Chariot Plane with lugs instead of bridge, showing influence of Badger. Photo from Ar. Clarence, Pinterest.

A definitive Norris no. 10 mitre plane with a curved gunmetal bridge with cupid’s bow in back is shown rebadged as a Buck at the bottom of this page. There are no differences between the Buck and a Norris no. 10 other than the stamp on the bridge.

Below you can see the curved bridges of both Norris and Holland. The influence of Holland on Norris is obvious. And that applies to the three previous Buck mitre planes as well.

Holland mitre plane, formerly from the Max Ott collection. Stamped “J. HOLLAND” on underside of bridge. 2 dovetails in front of the mouth; 3 dovetails behind. Nibbed Ward iron.

93 York Road was the former workshop and living quarters of Charles and Isabella Badger. Charles Badger died 28 September, 1869.

York Road was a busy thoroughfare, which ran between Waterloo Road and Westminster Bridge Road, with the large South Western Railway Station positioned in between these two intersections. 93 York Road was a good, high visibility workshop location for Charles Badger (1868-1869), and John Holland (1870-1890). Thomas Norris Jr. and Sr. rented 23 York Road from <1898-1915.

“Gunmetal, iron, plane, saw, file. & mechanical tool maker & dealer:” Holland was making a wide range of products. Not just planes.

Many Holland planes were bought in by tool dealers such as George Buck, many were stamped “J. Holland,” and many were sold unmarked. Holland was a prolific maker, and having a crew of two men–and an apprentice or two–made this possible.

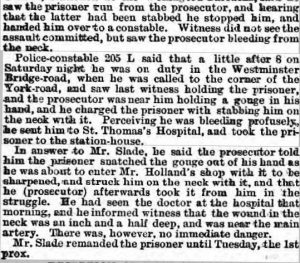

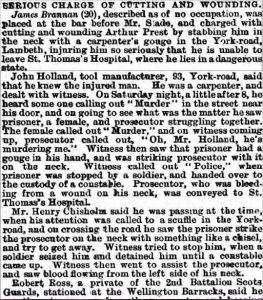

John Holland was involved in two newsworthy incidents during his career:

Here is John Holland’s second newsworthy event, published in the Clerkenwell News, 24 April, 1885:

Yesterday shortly before ten a loud explosion was heard in the neighbourhood of Westminster Bridge Road causing considerable alarm. The police ascertained that a serious explosion had occurred at the tool and cutlery establishment of Mr. Holland at 93, York Road. It appeared that at the time the son of the proprietor Samuel Holland aged 17, upon entering the parlour at the rear of the shop had smelt strong of gas. Unfortunately he sought the cause with a naked light, shattering the windows in the shop and damaging the display trade, which fortunately will not prevent the business from being carried on as usual.

By the 1891 U.K. census, John Holland was living at 25 St. Mary’s Square in Lambeth, while the P.O. directories listed Holland at 26 Richmond, St. George Road through 1893. After John Holland left 93 York Rd., he did not retire.

John Holland, “Toolmaker,” and his family, living at 25 Saint Mary’s Square, Lambeth, during the 1891 U.K. Census.

John Holland moved to 30 Garden Row sometime before the fall of 1894, and stayed there until at least 1907. He continued to make tools during this time.

Holland and his family remained involved in gunmetal and iron planemaking as well as making other woodworking tools into the twentieth century. Sons Harold C. and Samuel became involved in the tool business to various degrees in the 1890s and into the early 20th centuries at several addresses. During the 1901 census, John Holland, 70, declared his job as a “Carpenter and Joiner,” and was living at 30 Garden Row, in Southwark along with his younger sister Mercy, 66. John was listed in the London P.O. Directory for 1902 as a “Tool Manufacturer.”

By 1905, Holland had been working for over 55 years.

1907 was John Holland’s final year in business at 30 Garden Row, Lambeth.

In 1901, John Holland and Sophia Swann Holland were no longer living together; Sophia moved to 335 Battersea Park Road to live with her daughter, Mary A. Holland, who was working at a Coffee House Keeper. Sophia, aged 66, was working in a grocery store. Most likely, Mary and Sophia chose to live in Battersea because sons Harry and Samuel were both located in Battersea, working as tool dealers from 70 Falcon Road. Ten years later, Mary and Sophia were still in Battersea, living at 51 Eland Road, Lavender Hill, and Mary was working as a “Carver” in a restaurant. John Holland’s 30 Garden Row address in Southwark was three miles away.

![]() John Holland, 80, was listed as a retired “carpenter,” in the Tooting Bec Asylum, Wandsworth, during the 1911 U.K. census; senility must have overcome him by around 1907, when he stopped working.

John Holland, 80, was listed as a retired “carpenter,” in the Tooting Bec Asylum, Wandsworth, during the 1911 U.K. census; senility must have overcome him by around 1907, when he stopped working.

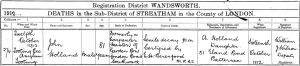

John Holland passed away in Wandsworth on 12 October, 1912. 81 (actually 82) was truly an advanced age for the time. John Holland was one of the most long lived planemakers compared to all his peers.

John and Sophia Holland were reunited in death. This part of Ladywell and Brockley cemetery has been overtaken by trees. Photo by Steve Johnson, 2020.

John Holland was interred with his eldest son James Henry, who died 24 October, 1881 at the age of 28, leaving a wife and two young children. James Henry was also a tool dealer. John, James, and Sophia, who died in 1915, were all buried at the Ladywell and Brockley cemetery, in Lewisham, an outer borough Southeast of London.

John Holland’s decision to move to Wandsworth may have been influenced by planemaker Thomas Norris (1835-1906). Norris had already moved to 6 Quarry Road in Wandsworth by 1900, as recorded in the P.O. Directory. John Holland and Thomas Norris had been longtime neighbors in Lambeth, they must have consulted each other as influences between them are apparent in their planes. This does not necessarily imply that there was a formal collaboration between them; sole proprietors by definition have always been recognized for having a strong independent streak. It was also likely that John and Thomas were friends. Thomas Norris was born in Lambeth, and he remained there to live and work until his move to Wandsworth.

© 2024 – Martin Shepherd Piano Service Using the text, research, or images on this website without permission on an ebay auction or any other site is a violation of federal law in most countries.

Some Norris Family History

Thomas’ parents were George Norris (1773-1845), and Rebecca Cooper, (1775-1843). George and Rebecca were married in 1802.

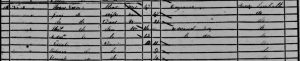

Thomas (1804-1886) and Jane (1803-1871) had the following children: Jane (1831-1878), Thomas James (1835-1906), Edmund (1837-1928), Sarah, (1840-1910), Rebecca, born 1842, Harriet Mary, (1847-1919), and Warnell, born 1847.

Edmund Norris was a small boat maker: masts, sails, oars, and sculls.

Thomas James Sr. was an engraver on George St. in Lambeth.

Thomas Sr, 16, was listed as an “errand boy” in the 1851 U.K. census.

Thomas married Eliza Knott (1839-1918), and surviving children (from as many as 7) included: Thomas James (1860-1936); Ada Jane, (1862-1944); Clances (1868-1871>), Elizabeth (1870-1949); Edith A.(1874-1959). In 1859, Thomas Norris declared his profession as a “tool maker.”

Thomas Norris Sr., and Jane, with Jane Knott, born 1857, 25 King’s Head Yard, Lambeth. 1861 U.K. census.

In 1861, Thomas Sr. and Jane were taking care of Jane Knott, granddaughter, born 1857.

Thomas Norris (1804-1886) was a “music engraver,” which was a skill that involved a great deal of precision. By the 1870s and 1880s, Norris the elder was admitted several times to the workhouse.

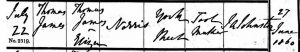

Thomas J. Norris was born 27 June, 1860, and was baptized 22 July, 1866 at St. John the Evangelist, Lambeth.

.

Thomas Norris Jr. (1860-1936) was the oldest son: first the apprentice, then partner and successor to his father in the business of making tools. Both father and son were baptized on 22 July.

Thomas J. Norris Sr.’s early success as a plane and toolmaker was due, in major part, to his business relationship with George Buck. Many early Norris planes were bought in by Buck and rebadged “BUCK.” This connection between Buck and Norris, was far from exclusive, however. A Buck infill plane with what appears to be Norris-like features may actually not be made by Norris. John Holland had an established business relationship with Buck as well, and Holland had a major influence on Norris’ planemaking. The same could be said of Stewart Spiers. Mitre planes shown here serve as an example of Holland’s stylistic influence on Norris. Norris did establish a tool making business circa 1860, so it turns out that later Norris advertising was not an exaggeration.

Early census and city directory information for Norris indicate that he produced joiner’s tools of a general nature, rather than specializing in planes.

In the 1881 U.K. census, Norris entered his job as a “Plane Tool Maker.” Thomas Jr. also working with his father; he probably started circa 1875.

Thomas Norris 1890 London P.O. Directory, the earliest entry I have found to date specific to “Iron Plane Maker.”

Kelly’s London P.O. Directory for 1899. Earliest entry found to date with Thomas Jr. listed as partner.

After John Holland left 93 York Road in 1890, but before Thomas Norris rented 23 York Road <1898, the East side of York Road was renumbered. 93 York Road became no. 5 York Road.

In the Survey of London: Volume 23, Lambeth: Southbank and Vauxhall, published 1951, the East side of York Street was described thusly:

Nos. 3-13 (formerly nos. 91-96)

These houses were erected on the York Road frontage of Field’s property circa 1829. They form a simple terrace in stock brick having a continuous dentil cornice to the parapet above the second story. The individual houses are, however, emphasized by the rectangular recesses in the parapet over each and by the narrow vertical inset panels separating them. Nos. 3–9 have balconies, those to the remaining houses having been removed when shop fronts were inserted.

In the 19th century these houses were largely used by dramatic agents and as lodging houses for members of the theatrical profession who were in low water; they earned the sobriquet of Poverty Corner.

Nos. 15-23 (formerly Nos. 97-101)

These houses were similar in character to Nos. 3–13 though they were built a year or two later. They were demolished in 1950 for road improvements.

Nos. 57-69 (formerly Nos. 1-5 Commercial Place and Nos. 132 and 133 York Road)

These houses, dating from 1843–5, were among the last to be erected in the road.

Lambeth Ordnance Survey Map, circa 1872, showing locations of Planemakers Thomas Norris Sr., and John Holland.

Norris had moved to Wandsworth in late 1899, but continued to rent 57 York St. as well as 23 York Road, which was used in their 1908 catalogue. Note that York St. was fully populated in 1901. The buyouts and evictions were later, circa 1903-1904. Norris was still listed at 57 York St. in the London 1905 P.O. directory as seen above.

An improvement in means was the reason behind the Norris family leaving 57 York Street, rather than pressure from the railroad. Norris’ sales of fine metal planes were finally paying dividends. Norris employee Charles Henry Payne explained the move. Regarding 57 York Street, Payne revealed that “The Norris family lived in rooms above the works, and another family lived above that. As the family became better off they moved home to Quarry Road Wandsworth, but retained the works in York Street.”

Railroad map, circa 1900-1905, showing proposed area of eminent domain around York St. Map from George Anderson. George found this while researching at the Lambeth Archive, at the Minet Library.

Construction of the Waterloo station began in the 1840s, but it continued on and off throughout the remainder of the 19th century. By the early 1890s, it became clear that the piecemeal approach led to poor planning and that a more unified concept would require a complete rebuild. The only remaining structure from the the original would be the large supporting arches over the marshy soil.

Sketch of York Road in the 1940s with Norris’ rental at 23 delineated. Image from George Anderson, who found it doing research at the Lambeth Archive, Minet Library, in Lambeth.

Thomas rented 23 York Road from as early as 1898 to 1915, when costs from the Great War economy were felt throughout Europe. Thomas Norris Jr. survived the War with some government contracts which granted him access to the metals that he needed. Norris’ 1913 patent for a plane adjustment mechanism, both depth and lateral, solidified his position as the leading high end metal planemaker in the U.K.

Postcard of Sycamore Grove, New Malden, looking West, circa 1906, when Thomas Norris Jr. moved in. From the collection of George Anderson.

Senility was an issue during Thomas James Norris Sr.’s final months.

£230 would be about $32,250 today. Estate was dated 27 September, 1906.

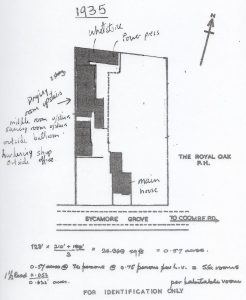

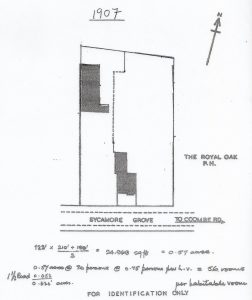

Thomas Jr. was on the move and went out and bought a home at 3 Sycamore Grove, New Malden on 23 September 1906. Soon after, work began on building a fairly large new workshop/factory on the land next his Victorian house. Money was available for construction, but not for a headstone at Thomas Sr.’s grave.

3 Sycamore Grove is on the right, with just a corner of the house exposed. Thank you George Anderson for these wonderful images! The Norris property had a 120 foot frontage, with a 200 foot depth, and the shop was built circa 1907-1909.

Map with footprint of workshop/factory and house at 3 Sycamore Grove, New Malden, circa 1935. From collection of George Anderson.

Map with footprint of 3 Sycamore Grove, New Malden, with house and proposed workshop, circa 1907. From collection of George Anderson.

Thomas Jr., 49, married Helen Sellars Walker, 44. It was a late marriage for both of them. Helen was living at 6 Quarry Rd., Wandsworth, Thomas Sr.’s former house.

The Royal Oak Pub, at 90 Coombe Road, was Norris’ neighbor on the East side of 3 Sycamore Grove. This map was drawn up about 10 years before Thomas Norris took possession of the property.

Sycamore Grove photo, looking East, towards Coombe Road. Photo from the collection of George Anderson.

This photo was taken circa 1900, and was found in the Lambeth Archive, at the Minet Library. A horse drawn wagon was used for delivering goods to the Royal Oak Pub, and you can see the silhouette of a person on the sidewalk. In the left foreground was the sidewalk frontage of “Marizion,” 3 Sycamore Grove, Norris’ home and workshop.

Buck: 100 Years

Left to right: Buck/Towell 245 Tottenham Court Road (1831-1861); Buck/Holland 245/(247) Tottenham Court Road (1861-1866); Buck/Holland 247 Tottenham Court Road (1867-1879); Buck/Holland 242 Tottenham Court Road (1880-1890); Buck/Norris No. 10 “Tot. Court Rd.”(late1880s-<1914); Norris (Morris) A11 which was included in the 1938 Buck & Hickman Catalogue.